- Home

- Good advice on flooring

- Floor coverings

- Wooden floors

- Materials and types

- Acoustic panels

- Tailored rugs

- Bamboo floor and boards

- BeefEater gas grill

- Table tops & table legs

- Design floors

- Tiles and clinker

- Good advice on flooring

- Carpets

- Floor heating

- Grass carpets

- Cork floors

- Kitchen, bath & wardrobe

- Laminate floors

- Linoleum floors

- Paint, Tissue & Putty

- Mats

- Needle felt and fair carpets

- Furniture

- Care products

- Remainders & good offers

- Stavparket / Sildebensparket

- Carpet tiles

- Terrace boards

- Accessories

- Wooden floors

- Product samples

- Vinyl flooring

- Tool

- Other products

- Ceiling and wall panels

- Nice floors

- Pine floor

- Click floors

- Ordered goods

-

Hot41% Off

-

Hot46% Off

-

Hot25% Off

-

Hot54% Off

-

Hot54% Off

-

47% Off

Materials and types

All information on this page is copied material from Gulvfakta, which is a technical reference material, Source: Gulvfakta

Wooden floors are divided into different categories according to their constructive structure

Load-bearing floors which can be divided into:

• Floors on joists

• Floors on joists

Non-load-bearing floors which can be divided into:

• Floating floors

• Glued floors

• Nailed floors

In this chapter, the most used types of wooden floors are reviewed.

1.7.1.1 Floor boards

1.7.1.2 Parquet boards

1.7.1.3 Stavparket

1.7.1.4 Parquet treads

1.7.1.5 Mosaic parquet

1.7.1.6 Lamellar parquet

1.7.1.7 Veneered boards

1.7.1.8 Brick floor

1.7.1.9 High-edge parquet

1.7.1.10 Block mosaic

All information on this page is copied material from Gulvfakta, which is a technical reference material, Source: Gulvfakta

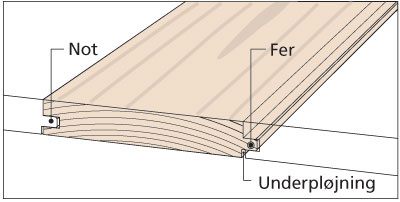

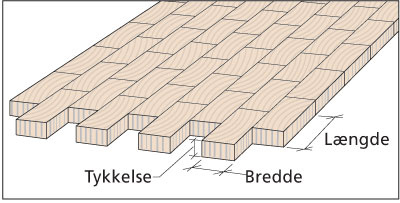

1.7.1.1 Floor boards

Floor boards are solid boards made of pine , spruce, Douglas fir, etc. Hardwood, e.g. oak and merbau, is only used to a lesser extent.

Floor boards are planed and plowed boards that are usually available in widths from 75 to 180 mm and in thicknesses from 14 to 30 mm. Standard products can be delivered to order up to 40 mm in thickness and 450 mm in width. The length is generally between 1.8 and 5.4 m. If delivered in decreasing lengths, some of the boards in a delivery may be shorter. If delivered in fixed lengths, a part of the lot, often 5-10%, will be delivered in shorter lengths for reasons of utilization of the raw material.

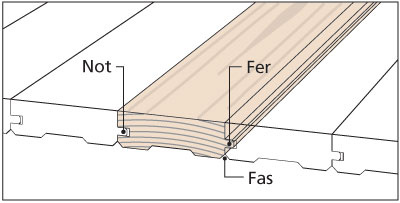

Fig. 1. Floorboards.

Fig. 1. Floorboards.

Board floors are sometimes called plank floors, although none of the products have sufficient thickness (planed, straightened at least 42 mm) to be called planks. The boards alone have a plank-like appearance.

Boards that are at least 20 mm thick can be laid on beams or joists as a load-bearing floor. The support distance must be adapted to the thickness and the load, see tables 4 and 5. For smaller board thicknesses, full support of the floor surface is required.

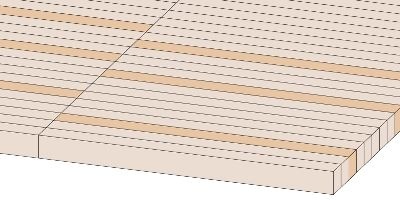

1.7.1.2 Parquet boards

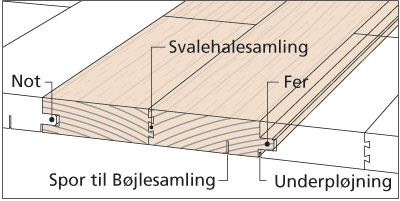

Parquet boards

Parquet boards are solid single planks that are assembled into boards at the factory. Usually two parallel rows of rods are used, joined together with a special dovetail joint. The boards are provided with tongue and groove on all four sides, and are available in lengths like ordinary floorboards.

Fig. 2. Parquet boards.

Fig. 2. Parquet boards.

Parquet boards can be laid in the same way as ordinary floor boards, i.e. as a load-bearing floor when the board thickness is at least 20 mm, or as a nailed floor.

Parquet boards can also be used for floating floors, which are assembled with hangers or clips (gluing the boards together is usually not applicable to parquet boards).

1.7.1.3 Stavparket

Stavparket

The stave park is single staves, usually in solid wood. The staves are rectangular with tongue and groove. Solid wooden parquet is also available without tongue and groove. Stavparket is made from the traditional European wood species such as beech, oak and ash, as well as from a number of overseas wood species, e.g. padouk, merbau, doussie, jatoba and wengé. The poles are usually 200-700 mm long and 50-70 mm wide. The thickness is normally 15-22 mm. For rods without tongue and groove, the length must not exceed 300 mm, and the thickness can be down to 10 mm. Parquet poles are also made as so-called long poles, which have a length of 700-1200 mm.

Fig. 3. Stavparket.

Fig. 3. Stavparket.

A wooden floor in the stick park is laid either as a glued or nailed floor. Long poles that are at least 20 mm thick can also be laid as a load-bearing floor.

1.7.1.4 Parquet treads

Parquet treads are made from single sticks that are glued together at the factory to form larger units. Parquet flooring is normally laid as a glued floor, but there are some types that can be used for floating floors, although only on smaller areas.

1.7.1.5 Mosaic parquet

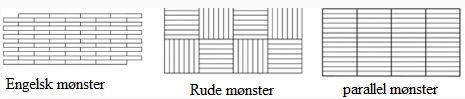

The mosaic parquet is usually 8 mm thick, the length and width of the rods can vary from manufacturer to manufacturer. The most common rod size is 23 x 160 mm. The rods are glued to the net and delivered in units corresponding to approx. 0.20 m2. The 3 patterns shown below are the most common

The hard types of wood are the most used, with oak and ash as the dominant ones, of the exotic types of wood, merbau is most often used, but in principle all hard types of wood can be used. The mosaic parquet is a wooden floor with a pattern that gives life and play to the room.

The mosaic parquet requires a flat and dry surface. The fields are mounted with wet glue, it is recommended to use a glue that does not contain water. Immediately after laying, the parquet is rolled to ensure that the sticks are pressed uniformly into the glue. When the glue has hardened, the mosaic parquet must be sanded, varnished and surface treated. The production tolerances on the mosaic park are relatively large and there will therefore be cracks/fissures between the rods after gluing. After the floor has been rough sanded (1st time sanding), the sanding dust is mixed with a special "putty liquid". The floor is puttyed with this mass, whereby cracks and other things are filled with "lacquer putty". The mosaic parquet reacts more quickly to changes in the humidity of the air than other solid parquet. The mosaic park is best in a stable indoor climate with small fluctuations in the humidity of the air.

1.7.1.6 Lamellar parquet

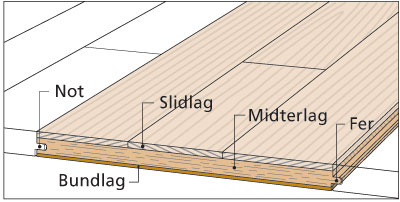

Laminate flooring is usually constructed as a three-layer construction. At the bottom, a bottom layer of softwood with the fibers in the longitudinal direction of the board. A middle layer or barrier layer of e.g. chipboard, plywood, MDF or crossed slats of hardwood or softwood. At the top, a wear layer which is at least 2.5 mm thick, but which in most slatted boards has a thickness of 3-4 mm. The wear layer can be made of one piece of veneer or divided like wooden parquet. Laminate parquet is therefore available with the appearance of floorboards, parquet or patterned parquet. A lamella parquet is a wooden floor that is warm and soft to walk on, and which is extremely easy to clean. A slatted parquet is available in many types of wood, such as oak, pine, beech, etc.

Fig. 5. Slatted boards.

Fig. 5. Slatted boards.

The laminated parquet is equipped with tongue and groove on all four sides and is also available with a locking tongue and groove system (click system), which eliminates the need for glue in tongue and groove when laying floating floors. Laminate flooring can also be laid as a glued or nailed floor, or as a load-bearing floor if the board thickness is at least 22 mm.

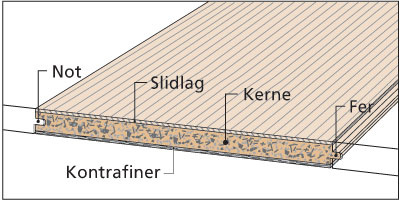

1.7.1.7 Veneered boards

Veneered boards consist of a wood-based core, e.g. chipboard, MDF or HDF. The wear layer is a thin, varnished veneer that is less than 2 mm thick. The back is "contrafined" to counteract tension in the material, so the floorboards remain flat.

Fig. 6. Veneered boards.

Fig. 6. Veneered boards.

Veneered wooden floors are supplied with wear layers in a wide range of wood species and with surfaces such as boards or with a parquet pattern. Veneered boards are laid as a floating, glued or nailed floor.

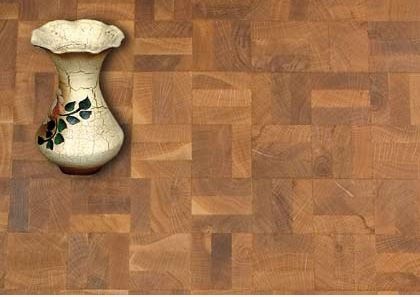

1.7.1.8 Brick floor

Blocks are right-angled wooden blocks made of oak, pine, spruce or larch. The length of the bricks for brick floors should not be more than 1.5 times the width. Blocks are available in thicknesses from 18 to 100 mm.

The blocks are laid down with the fiber direction vertical. They are glued directly to the substrate with a special adhesive.

Fig. 7. Bricks.

Fig. 7. Bricks.

The most suitable substrate is a rigid wooden board subfloor. The blocks can also be glued to a dry concrete subfloor. Finally, the wooden blocks can be laid down in sand. Bricks of the best quality can be laid, sanded and surface treated so that they can be used in meeting rooms and homes. As the surface of a brick floor is endwood, it easily absorbs moisture from the air or from floor washing. Direct exposure to moisture should therefore be avoided. It is always recommended to consult with the supplier regarding moisture expansion and the need for expansion joints. Brick floors are particularly suitable for floors in industry, e.g. mechanical workshops, as they provide a robust and hard-wearing floor at the same time that things that are dropped on the floor, e.g. machine parts and tools, are less prone to damage.

1.7.1.9 High-edge parquet

The high-edge kick is normally delivered in approx. 23 mm thickness, but can also be delivered in approx. 10 and approx. 16 mm thickness. The rod width is 8 mm and the length is usually 160 mm. A laying unit consists of 40 rods in a row, which is why the unit is 160 x 320 mm. The high-edge parquet is made from wood species such as ash, oak, red oak and merbau, and is delivered untreated.

Fig. 8. The high edge kick.

Fig. 8. The high edge kick.

The laying process is the same as the laying process for the mosaic parquet. The high edge parquet must also be varnished

1.7.1.10 Block mosaic

Brick mosaics are thin approx. 8 mm endwood washers. The blocks are delivered glued to a mesh in a checkered pattern. Each net is approx. 0.2 m2. The size of the individual "bricks" can vary slightly, but typically they are approx. 60 x 20 mm. The hard woods are the most suitable. The brick mosaic is installed in the same way as the mosaic parquet. The brick mosaic is extremely sensitive to moisture. It must be laid in the best quality glue and you must make sure that the glue and the subfloor can withstand the tensile stresses that will arise when the brick mosaic is moistened