- Forside

- Gode råd om gulv

- Gulvbelægninger

- Trægulve

- Generelle forhold

- Akustikpaneler

- Afpassede tæpper

- Bambusgulve

- Bordplader & bordben

- Designgulve

- Fliser og klinker

- BeefEater gasgrill

- Gode råd om gulv

- Gulvtæpper

- Gulvvarme

- Græstæpper

- Korkgulve

- Køkken, bad & garderobe

- Laminatgulve

- Linoleumsgulve

- Maling, Væv & Spartel

- Måtter

- Møbler & Boliginteriør

- Nålefilt og messetæpper

- Plejeprodukter

- Restpartier & gode tilbud

- Sildebensparket & Stavparket

- Tæppefliser

- Terrassebrædder

- Tilbehør

- Trægulve

- Vareprøver

- Vinylgulv

- Værktøj

- Øvrige produkter

- Loft- og vægpaneler

- Flotte gulve

- Fyrretræsgulv

- Klikgulve

- Bestilte varer

-

-26%

-

Populær29,00 DKK

-

Populær21,00 DKK

-

29,00 DKK pr m2

-

29,00 DKK pr m2

Generelle forhold

Alle informationer på denne side er kopieret materiale fra Gulvfakta som er et fagteknisk opslagsmateriale, Kilde: Gulvfakta

1.7.2.1 Sorteringer

1.7.2.2 Mærkning

1.7.2.3 Tolerancer

1.7.2.4 Overfladebehandling

1.7.2.5 Trægulve og fugt

1.7.2.6 Måling af fugtindhold i træ og træplader

1.7.2.7 Lyd i trægulve

Alle informationer på denne side er kopieret materiale fra Gulvfakta som er et fagteknisk opslagsmateriale, Kilde: Gulvfakta

1.7.2.1 Sorteringer

Træ er et naturmateriale med mange og varierende egenskaber. Det er det der gør det så underfuldt, men også et faktum, der kan give mange diskussioner og overvejelser. 2 stykker træ fra den samme træsort, træ kan have markant forskelligt udseender. Der er flere årsager til dette.

• Træs vækstbetingelser, i form af forskelle i jordbunden og nedbørsmængder kan påvirke veddet.

• Naturlige farveforskelle i træstammen, kan for nogle træsorter give meget store variationer i udseendet af de produkter der fremstilles af veddet. (kerneved contra splintved)

• Antallet og størrelsen af kaster.

Trægulve leveres i derfor i ofte forskellige klasser sorteret efter udseende. Sorteringerne kan ske efter klasserne O, □, eller ∆, defineret i produktstandarderne for de enkelte gulvtyper. Det mest almindelige er dog at producenterne definerer deres egne sorteringskriterier, hvilket gør at sammenligninger mellem forskelle fabrikater vanskelig. Herudover vil overfladebehandling være særdeles væsentlig for gulves samlede udtryk. Ved valg af trægulv anbefales det at man beder leverandøren om store repræsentative prøver. Ved gulve der leveres uden færdig overflade kan det være relevant at få lagt et mindre prøvegulv, i den sortering og med den overflade som man ønsker. Der henvises i øvrigt til leverandørernes informationsmateriale for konkrete sorteringsklasser.

1.7.2.2 Mærkning

Trægulve skal CE-mærkes.

Det er den harmoniserede standard DS/EN 14342 "Trægulve - Karakteristika, vurdering af overensstemmelse og mærkning", som vil ligge til grund for CE-mærkningen, der gælder for produktion og anvendelse i Europa. Det er producenten eller den forhandler, der importerer trægulvene, som vil være ansvarlig for CE-mærkningen.

De egenskaber, der stilles krav til, fremgår af anneks ZA i DS/EN 14342:

• Reaktion ved brand

• Afgivelse af formaldehyd

• Indhold af pentachorophenol

• Brudstyrke (maksimal belastning)

• Skridsikkerhed

• Varmeledningsevne

• Holdbarhed

Som tillæg til standarden kan der være udarbejdet nationale krav i det omfang, det er nødvendigt for at overholde byggelovgivningen.

CE-mærkning er ikke et kvalitetsmærke, men et harmoniseret standardblad, der virker som gulvbelægningens rejsepas inden for det europæiske fællesskab.

CE-mærket vil typisk indeholde følgende oplysninger for massive parketstave i brandklasse Cfl-s1, jævnfør DS/EN 14342 - tabel 1:

Som et supplement til CE-mærkningen skal alle produkter til byggeindustrien have en ydeevnedeklaration.

Ydeevnedeklerationen tildeles et unikt nummer og indeholder informationer om:

1. Byggevaretypen

2. Byggevareidentifikation

3. Byggevarens tilsigtede anvendelse®

4. Fabrikantens navn og adresse

5. Navn og adresse på bemyndiget repræsentant

6. Systemer for vurdering og kontrol af byggevarens ydeevne (Avcp)

7. Notificeret organ(er)'s opgave(r) , hvis relevant, herunder beskrivelse af hvad de har udført, med reference til relevante systemer

FSC - Mærkning.

Forståelsen af "behovet for at anvende træ fra bæredygtigt skovbrug" vinder større og større indpas hos de danske forbrugere. FSC ordningen er en af de dominerende ordninger der giver denne sikkerhed.

Når du som forbruger eller virksomhed vælger FSC, er du med til at sikre naturen og de sociale forhold i de skove, som træet kommer fra. Dette gælder, når du køber eller producerer produkter af FSC-certificeret træ - lige fra havemøbler og gulve til papir og emballager.

FSC's arbejde bygger på de samme 10 grundprincipper over alt i verden. På nationalt plan videreudvikles / tilpassen principperne med afset de lokale forhold.

FSC's 10 grundprincipper:

1. Overholdelse af love

Skovdriften skal overholde gældende lovgivning, regulativer, og nationalt ratificerede internationale traktater, konventioner og aftaler.

2. Arbejderes rettigheder og arbejdsvilkår

Skovdriften skal opretholde eller forbedre de sociale og økonomiske forhold for dem, der er beskæftiget i skoven.

3. Oprindelige folks rettigheder

Organisationen (skovejer) skal identificere og anerkende oprindelige folks juridiske og traditionelle rettigheder til ejerskab, benyttelse og brug af land, territorier og ressourcer, der påvirkes af driften.

4. Forhold til lokalsamfundet

Organisationen (skovejer) skal bidrage til at opretholde eller forbedre de sociale og økonomiske forhold for lokalsamfundet.

5. Skovens ydelser

Skovdriften skal effektivt forvalte skovejendommens mange produkter og ydelser for at opretholde eller forbedre den langsigtede økonomiske levedygtighed og udvalget af sociale og miljømæssige ydelser.

6. Miljøværdier og -påvirkninger

Organisationen (Skovejer) skal vedligeholde, bevare og genetablere ydelser og miljøværdier fra skovens økosystem og skal undgå, udbedre eller mindske negative miljøpåvirkninger.

7. Driftsplaner

Organisationen (skovejer) skal have en driftsplan, der er i overensstemmelse med dens politikker og formål og tilpasset i forhold til driftens skala, intensitet og risiko. Driftsplanen skal implementeres og holdes opdateret baseret på information fra monitering for at fremme en tilpasset skovdrift. Den tilhørende proceduremæssige dokumentation skal være tilstrækkelig til at vejlede personale, informere berørte og interesserede interessenter og begrunde driftsmæssige beslutninger.

8. Overvågning og vurdering

Organisationen (skovejer) skal demonstrere, at fremgang i forhold til at opnå målsætninger, effekten af driftsaktiviteter og forholdene for driftsenheden moniteres og evalueres, i forhold til driftaktiviteternes skala, intensitet og risiko, for at kunne implementere en tilpasset drift.

9. Høje bevaringsværdier

Organisationen (skovejer) skal bevare og/ eller øge de "høje bevaringsværdier" i skoven ved at benytte forsigtighedsprincippet.

10. Implementering af driftsaktiviteter

Driftsaktiviteter, der udføres af eller for skovejendommen, skal udvælges og implementeres i overensstemmelse med organisationens (skovejers) økonomiske, miljømæssige og sociale politikker og målsætninger og være i overensstemmelse med de samlede principper og kriterier.

* Principperne blev revideret og godkendt i starten af 2012. Den danske FSC-skovstandard er ved at gennemgå en revidering, så den kommer til at stemme overens med de reviderede principper. Den nuværende FSC-skovstandard er således ikke baseret på de reviderede principper. Vil du vide mere omkring FSC, henvises til www.dk.fsc.org

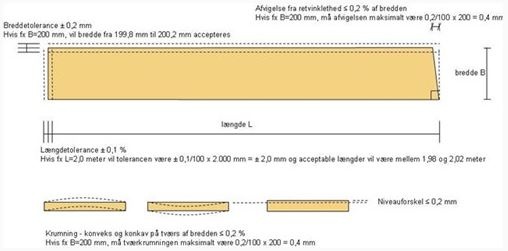

1.7.2.3 Tolerancer

Tolerancer.

Et trægulv er lavet af et levende materiale og ved produktionen kan der også forekomme mindre tolerancer. Dette bevirker at der ved et nylagte trægulve kan der forekomme åbninger mellem stavene/brædderne. De produktionsmæssige tilladelige tolerancer er beskrevet i en række EN-normer. Nedenstående figur viser de tolerancer et bræt/en stav skal overholde. De viste tolerancer er produktionstolerancer. Og man skal være opmærksom på, at træets dimension også påvirkes af ændringer i luftfugtigheden. Dette kan medføre ændringer der gør at tolerancerne overskrides.

Når man taler om mål (meget nøjagtige mål) i f.b.m. trægulve er dette kun meningsfuldt, hvis man har styr på omgivelserne. En parket stav på 60 - 70 mm. i bredden kan ændre sig 0,5 mm. i bredden som følge af de (tilladte og forventelige) ændringer i luftens fugtindhold.

Se også afsnit "Træ og fugt".

Ovenstående er vigtigt at have in mente når man vurderer resultatet, kvaliteten, af et nylagt gulv. Det er ligeledes vigtigt at understrege følgende; Bedømmelsen af et trægulvet skal foretages stående (i en højde af ca 160 cm.) med lyset i ryggen.

1.7.2.4 Overfladebehandling

Overfladebehandling inklusiv afslibning er beskrevet under vedligeholdelse, klik her for at læse mere

1.7.2.5 Trægulve og fugt

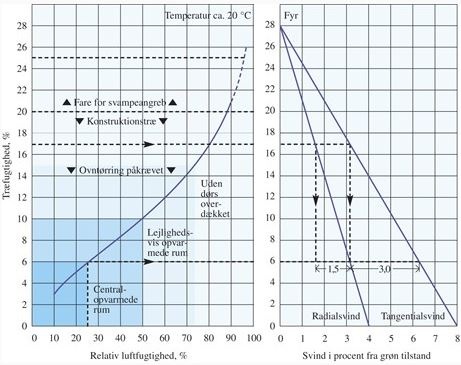

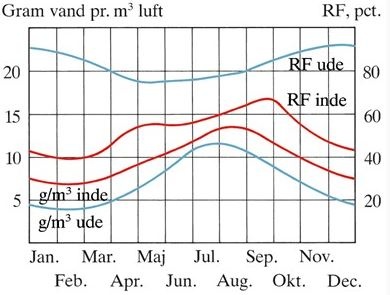

Ved projektering og lægning af trægulve skal der tages hensyn til de uundgåelige dimensions ændringer, der vil forekomme som følge af ændringer i de omgivelser, hvor trægulvet ligger. Over året varierer luftens fugtindhold, dette påvirker trægulve. På figur 1 ses hvorledes luftens absolutte fugtighed og luftens relative fugtighed variere over året,

Træ er et organisk materiale, og består overordnet af forskellige typer af celler. I levende tilstand er cellerne og cellevæggene fyldt med vand og der foregår en konstant vandtransport, via cellerne, rundt i træet. Når træet fælles stopper vandtransporten og vandt i cellevæggene tørrer bort, udtørringsprocessen stopper når der er opnået en ligevægtstilstand mellem den fugt der er i træet og den fugt der er i den omgivende luft. Cellerne i det "døde" træ kan også optage fugt fra luften, hvis luften indeholder mere vand end træet gør, hvorved en ny ligevægt tilstand indtræder. I forbindelse med optagelse og afgivelse af vand til omgivelserne ændrer træet dimension. Når det optager fugt vokser det (kvæller) når det afgiver fugt svinder det, det bliver mindre. Det er denne proces, man skal have in mente, når man projekterer og lægger trægulve.

Figur 2: Fugtligevægtskurven/sorptionskurven (til venstre) viser sammenhængen mellem den relative luftfugtighed ved ca. 20°C, og kurven til højre viser beregning af svind ved ændring af ligevægtsfugtigheden. Hastigheden, hvormed vandet optages/afgives i trægulvet kan påvirkes ved at give træet en overladebehandling. Jo tættere overfladebehandling man giver trægulvet, jo langsommere reagerer det. Herud over er gulvets tykkelse også en vigtig parameter. Tykke brædder/stave er længere tid om at opnå en ligevægtsfugt end tynde brædder/stave.

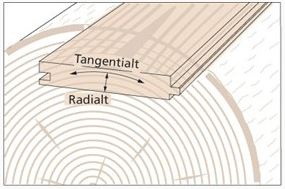

Den fugt betingede dimensionsændring er ikke ens i træets hoved retninger.

Normalt er det tangentielle svind ca. dobbelt så stort som det radiale svind og det aksiale svind kun mellem en 1/10 og en1/20 af det radiale, hvorfor der ofte ses bort fra dette. Ydermere vil der være densitets forskelle mellem ved fra træets rod og træets top. Denne forskel påvirker også svindet.

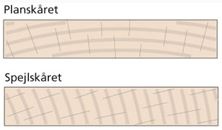

Svind og udvidelse i træ afhænger af opskæringen/årringsplaceringen.

En række af de, til gulv, mest anvendte træsorter (fyr, bøg eg og ask) reagerer som følger: En ændring i træets fugt indhold på 1. procent vil give en ændring på ca. 0,15% radialt og 0,30% tangentielt. I praksis er træ til paket-/bræddegulve en blanding mellem planskårne og spejlskårne enheder og man anvender derfor et gennemsnitstal på 0,22% eller 2,2 mm./m.. for hver procent træ

Eksempel 1.

Et parketgulv med 65 mm. bredde stave leveres fra fabrikken med et gennemsnitligt fugt indhold på 8%. Gulvet lægges i forsommeren ved 20°C og en relativluftfugtighed på ca. 40% i et lokale der er 4 meter bredt. I løbet af sommeren forventer man at luftens relative fugtighed vil stige til 65%. Dette vil medføre at parketstavenes gennemsnitlige fugtindhold vil stige til ca. 13% (se figurG2) d.v.s med ca. 5% i f.h.t fugtindholdet på lægningstidspunktet. Denne fugtstigning vil medfører at parketstavene i gennemsnit vil udvide sig med 5x0,22%x65mm=0,7 mm. Målt over hele lokalets bredde vil parketgulvet således udvide sig med 4000/65x0,7 = 43 mm på grund af forandringen i luftens fugtindhold.

Fugtens betydning for trægulve

Ved valg og udførelse af trægulve må der tages hensyn til de uundgåelige dimensionsændringer som følge af årstidsvariationerne i luftfugtigheden. Fuger mellem gulvbrædder kan ikke undgås, men ved valg af gulv kan størrelsen af fremtidige fuger begrænses. Fuger her er åbninger mellem brædder eller stave i gulvet.

Fugestørrelsen kan reduceres ved at:

• Bruge smalle brædder i stedet for brede, fordi fugebredden følger bræddebredden.

• Vælge produkter med lille dimensionsændring som følge af fugt.

• Styre klimaet, f.eks. ved moderat opfugtning i kontorhuse om vinteren for at undgå udtørring.

• Undlade at bruge gulvvarmeanlæg eller strålevarme i lofter.

• Fugerne er altså forholdsvis store, og i praksis vil fugerne desuden ofte være af forskellig størrelse, hvilket bevirker stor risiko for et utilfredsstillende udseende.

Bemærk, at hvis der i stedet havde været anvendt et 180 mm. bredt gulvbræt, ville fugerne i stedet være henholdsvis ca. 1,2 og 4 mm.

Eksempel 2

Et traditionelt fyrretræsgulv har 18 brædder pr. 2 meter. Gulvbrædderne er lagt uden mellemrum. Efter nogle måneder er der mellemrum mellem brædderne af varierende størrelse fra 0 til 5 mm. De 17 mellemrum er med en bladsøger målt til at have en samlet bredde på 48 mm. 48 mm. på 2 meter svarer til et svind på 2,4 %. Med et middel tværsvind på 0,22 % for hver én fugtprocents ændring skal der (2,4 % : 0,22 %) =11 % ændring i bræddernes fugtindhold til at give et svind på 2,4 %. Da den aktuelle træfugtighed er 7 %, har gulvbrædderne ved lægningen haft et fugtindhold på cirka 18 %.

10-brætsmål

Ved lægning af massivt trægulv skal der sørges for, at trægulvet får mulighed for at optage fugtbevægelser. Dette sker ofte ved at udlægge trægulvet efter et 10- brætsmål, som angiver den bredde 10 brædder eller stave forventes at have i den fugtigste brugstilstand. Den fugtigste periode er som regel eftersommeren, hvor gennemsnitsfugtindholdet i luften kan nå 65% RF med et deraf følgende fugtindhold i træet på 12 - 13 %, dog afhængigt af træart m.m.

I eksempel 1 beregnede vi at en almindelig parket stav på 60 - 70 mm udvider sig ca. 0,7 mm. pr. stav ved opfugtning fra det fugtindhold, hvormed stavene normalt forventes at blive leveret, til den ligevægts fugt den må forventes i den fugtigste periode. Mange gulve når ikke at opfugte til en ligevægtsfugt på 12-13%.

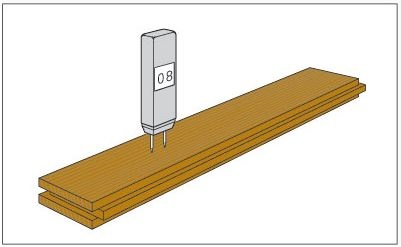

1.7.2.6 Måling af fugtindhold i træ og træplader

Den almindeligste metode til fugtmåling i træ er elektrisk modstandsmåling mellem to elektroder, som stikkes ind i træet, se figur 7. Metoden er baseret på, at modstanden mellem elektroderne er afhængig af træets fugtindhold. Der findes mange fabrikater men kun to hovedtyper af instrumenter.

Fig. 7. Måling af træfugt med elektrisk modstandsmåler. Målingen er baseret på måling af modstanden mellem to elektroder (ben) som stikkes ned i træet. Der skal måles på langs ad årene og mindst 300 mm. fra endetræ.

Den ene type har isolerede elektroder, så der kun måles ved spidsen af elektroderne. Dette kan være en fordel, fordi der ikke sker forstyrrelser, f.eks. på grund af kondens på overfladen. Den anden type instrumenter har uisolerede elektroder og er som regel billigere og nemmere at arbejde med. Der skal måles på langs ad årerne og ikke henover knaster eller i nærheden af søm eller skruer. De fleste instrumenter angiver direkte fugtindholdet i vægtprocent. Normalt er instrumenterne kalibreret til at måle i fyr og gran, og der må korrigeres ved måling i andre materialer, ligesom der må korrigeres ved temperaturer, der afviger væsentligt fra 20°C. Da trykimprægneringsmidler kan ændre træets ledningsevne, vil målinger i trykimprægneret træ give misvisende resultater.

1.7.2.7 Lyd i trægulve

Spændingslyde i et trægulv kan forekomme, og høres som mindre knase- eller knirkelyde. Det er helt normalt for et trægulv. Lyde kan være forskellige fra årstid til årstid, da træet udvider sig og trækker sig sammen efter temperatur og luftfugtighed.

I sensommeren er den relative fugtighed høj i vores boliger, og derfor øges fugtindholdet i trægulvet også. Den større fugtighed betyder, at gulvet udvider sig og måske kommer til at ligge i spænd, hvilket kan resultere i årstidsbestemte knirkelyde, når gulvet betrædes. Oftest forsvinder lydene igen, når fyringssæsonen sætter ind og den relative fugtighed stabiliseres.

I gamle bræddegulve på strøer kan knirkelydene også være forårsaget af slid og gentagne gulvafslibninger. Feren kan være blevet beskadiget, så to nabobrædder bevæger sig utilsigtet meget i forhold til hinanden, og derved skaber generende lyde, når man træder på gulvet. Ligeledes kan de bærende bjælker under brædderne være sunket, eller brædderne kan være slebet så mange gange, at brædderne bevæger sig i sømhullerne, når gulvet betrædes. En ødelagt fer er vanskelig at reparere, mens der findes forskellige metoder til at begrænse bræddernes bevægelse i sømhullerne.

Nye gulve lægges oftest som svømmende gulve, hvor der ikke kan være lyde fra sømhuller. Afhængig af ændringer i den relative luftfugtighed og den temperatur, som er i rummet, kan der forekomme mindre knirkelyde, hvilket er helt normalt. I tilfælde, hvor knirkelydene forekommer konstant og generende, kan årsagen eventuelt skyldes et skævt eller eftergivende undergulv, hvor uacceptable lunker eller forhøjninger i undergulvet skaber lydene, når gulvet belastes.

Der findes ingen standarder eller andre regler for, hvor meget et trægulv må knirke, men det bør aldrig forventes, at et trægulv er lydløst ved normal brug.