- Forside

- Gode råd om gulv

- Gulvbelægninger

- Fugefrie gulve

- Akustikpaneler

- Afpassede tæpper

- Bambusgulve

- Bordplader & bordben

- Designgulve

- Fliser og klinker

- BeefEater gasgrill

- Gode råd om gulv

- Gulvtæpper

- Gulvvarme

- Græstæpper

- Korkgulve

- Køkken, bad & garderobe

- Laminatgulve

- Linoleumsgulve

- Maling, Væv & Spartel

- Måtter

- Møbler & Boliginteriør

- Nålefilt og messetæpper

- Plejeprodukter

- Restpartier & gode tilbud

- Sildebensparket & Stavparket

- Tæppefliser

- Terrassebrædder

- Tilbehør

- Trægulve

- Vareprøver

- Vinylgulv

- Værktøj

- Øvrige produkter

- Loft- og vægpaneler

- Flotte gulve

- Fyrretræsgulv

- Klikgulve

- Bestilte varer

-

-26%

-

Populær29,00 DKK

-

29,00 DKK pr m2

-

Populær21,00 DKK

-

29,00 DKK pr m2

Fugefrie gulve

Alle informationer på denne side er kopieret materiale fra Gulvfakta som er et fagteknisk opslagsmateriale, Kilde: Gulvfakta

Ved fugefrie gulve forstås belægninger, der udlægges som mørtel eller i flydende form, og som efter hærdning udgør en sammenhængende gulvflade. Fugefrie gulve er karakteristiske ved, at de ikke behøver andre fuger end dem, der er nødvendige af hensyn til den underliggende konstruktion.

Gulvtypen eller gulvets areal kan imidlertid medføre, at der må udføres samlinger i gulvbelægningen.

1.5.0.1 CE-mærkning af fugefri gulvprodukter

1.5.0.2 Cement baserede gulve

1.5.0.3 Kalciumsulfat baserede gulve

1.5.0.4 Magnesit gulve

1.5.0.5 Asfalt baserede gulve

1.5.0.6 Hærdeplastgulve

1.5.0.7 Hulkeler - hærdeplastgulve

1.5.0.8 Afslutning mod gulvafløb

1.5.0.9 Skridhæmmende overflader

1.5.0.10 Valg af fugefri gulvbelægning

1.5.0.11 Funktionsanalyse - fugefrigulve

1.5.0.12 Rengøring

1.5.0.13 Forventninger til hærdeplastgulve

Alle informationer på denne side er kopieret materiale fra Gulvfakta som er et fagteknisk opslagsmateriale, Kilde: Gulvfakta

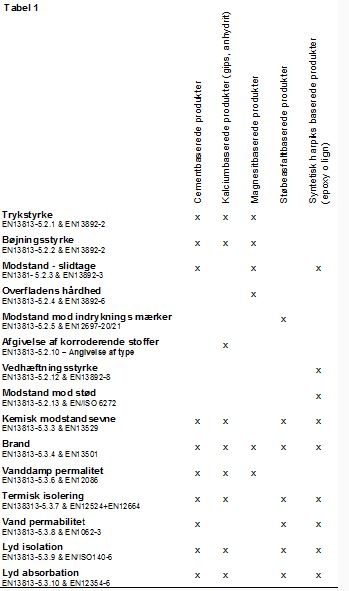

1.5.0.1 CE-mærkning af fugefri gulvprodukter'

Alle fugefrigulvprodukter der sælges på det danske marked skal være CE-mærkede i h.t. den fælles europæiske standart EN-13813. De værdier der skal deklareres varierer en smule fra produktgruppe til produktgruppe, se tabel 1.

Herudover kan producenterne angive en række andre egenskaber. Værdierne oplyses til forbrugerene i en ydeevne deklaration (DoP - Declaration of Performance). Ydeevne deklarationen er baseret på følgende principper:

Alle produkter skal som minimum gennemgå en række initialtest (førstegangsprøvning) til fastlæggelse af de egenskaber der skal deklareres. At producenterne via en løbende produktionskontrol (på niveau med ISO 9001) sikre ensartethed af produkterne. Se i øvrigt under "mærkning" for yderligere information om CE-mærkning. De fugefrie gulve dækker et meget bredt spektrum af produkter, og ydermere fremstilles mange af produkterne i adskillige varianter og tykkelser, ligesom der findes blandingsprodukter, fx beton/acryl og beton/asfalt. Dette gør det vanskeligt at give generelle retningslinjer. Der bør derfor altid indhentes information hos leverandøren, som kan give specifikke produktoplysninger, fx om krævet styrke af underlag (under hensyntagen til den forventede brugsbelastning) og modstandsevne mod kemikalier. Leverandøren kan også vejlede i hvilke produkter, der er mest velegnede til et givet formål.

Da fugefrie gulve udlægges flydende eller som mørtel, er kvaliteten af belægningen afhængig af korrekte anvisninger om opbygningen og af arbejdsudførelsen.

De tykkere fugefrie belægninger kan i en vis udstrækning eliminere ujævnheder i underlaget.

1.5.0.2 Cement baserede gulve

Basismaterialet for cement baserede fugefrigulve er hydraulisk bundne cement der består af standard- eller specialcement tilsat mineralske fyldstoffer, evt. puzzolaner og/eller polymerer. Disse produkter benyttes ofte som underlag for egentlige topbelægninger som tæpper, træ, linoleum m.v. De kan udlægges selvnivellerende og derfor velegnede til brug ved afretning af råbetongulve og gamle trægulve. Anvendt på denne måde kaldes de afretningslag eller tyndpudsgulve. Du kan læse mere om dette område i afsnittet omkring afretnngslag. I afsnittet omkring spartling er definitionerne på de forskellige spartelprocesser gennemgået. Fugefri cementbasserede gulve, kan også benyttes uden montering af en egentlig gulvbelægning. Anvendt på denne måde kaldes gulvene ofte for designgulv, New York'er gulve eller Pandomo gulve.

Designgulvene kan udlægges på ny udstøbte eller gamle betonunderlag og benyttes især, hvor der stilles store krav til hygiejne, slidstyrke eller kemiske og termiske belastninger. Herudover vælges gulvene også af dekorative årsager. Cementspartelmasse der eventuelt kan indfarves. Overfladen på gulvet forsegles med transparent overflade coating.

Krav til undergulvet

Undergulvets beskaffenhed er særdeles vigtig for resultatet af det færdige designgulv og rigtig mange af de overfladeproblemer man ser på designgulve kan henføres til problemer med undergulvet. Overfladestyrken (sammenhængsstyrken) skal mindst være 1,5 MPa, svarende til klasse C - erhverv. Undergulvet skal generelt være nedtørret til max 85% RF (men tjek altid med leverandøranvisningerne for det ønskede produkt). Herudover skal overfladen være fri for slamlag, voks (curing-membran) samt spild af olie, fedt, og lign. urenheder. For at sikre en tilstrækkelig ren overflade er det ofte nødvendigt at udføre en mekanisk afrensning af overfladen i form af en slyngrensning eller sandblæsning. Efter endt afrensning bør overfladen gennemgås grundigt for løseområder, skrukhed, revner m.v. Er overfladen meget ru/struktureret kan det være nødvendigt at slibe den eller udføre en spartling af overfladen.

For at sikre en optimal vedhæftning og for at forebygge pinholes, blærer o.lign. anbefaler de fleste leverandører at undergulvet forsegles. Dette gøres ved at prime overfladen om nødvendigt af flere omgange og eventuelt at lukke overfladen fuldstændigt ved brug af epoxybasserede produkter. Anvendes epoxybasserede produkter skal overfladen afsandes for at sikre den nødvendige vedhæftning.

Udlægning af spartelmassen.

Når undergulvet er klargjort og tørt, kan spartelmassen udlægges. De fleste produkter kan udlægges ved udpumpning eller manuel opblanding. Udlægnings-metoden skal vurderes i forhold til den konkrete opgave. De bedste resultater fås med produkter der ikke svinder (kun svinder meget lidt). Mange af de traditionelle spartelmasser udvikler ved størkningen svage svindrevner der er uden betydning, når overfladen efterfølgende pålægges en traditionel gulvbelægning, men svindrevner vil i forbindelse med designgulve ofte merføre bristede forventninger hos bygherre.

De fleste produkter kræver en lagtykkelse på min 5 mm. for at sikre en tilstrækkelig flydeevne. Inden udlægningen bør der udføres kantafgrænsninger langs vægge og i overgangene mellem rum. Er der dilatationensfuger i undergulvet skal de altid føres helt op til oversiden af designgulvet. Udlægningen bør derfor kun foregå hvis bygningen er tæt (vinduer og døre er monteret). I udlægnings- og afhærdningsperioden anbefaler de fleste leverandører at overflade og rumtemperatur er ca. 20°C. Arbejdsstedet skal beskyttes mod direkte træk og nedbør. Særligt fokus bør rettes mod lodrette rør-gennemføringer og andre potentielle utætheder. Disse skal tætnes omhyggeligt, således at spartelmassen ikke kan løbe ned. Efterspartling ved døre o.a. samt eventuelle reparationer er i praksis umuligt at udføre uden synlige overgange (overladen skal stå færdig førstegang).

Forsegling af overfladen.

Når designspartelmassen er tør skal overfladen forsegles i form af en coatning. Overflade coatningen bør ske umiddelbart efter gulvet er tørt da den ubehandlede overflade er særdeles modtageligt overfor smuds og snav, som kun meget vanskeligt kan fjernes.

Der findes forskellige produkter på markedet til overfladebehandling af designgulve. Hovedgrupperne er:

• Polyuretanbaserede topcoats

• Epoxy lakker med høj UV beskyttelse.

• Stenolier

• Voks.

Du bør altid kontrollere, hvilke overfladeprodukter producenten anbefaler til den spartelmasse du har valgt. Anvendes en produkt kombination der IKKE er anbefalet af producenten, vil garantien (som regel) bortfalde. Gulvets overflade ændre sig i forbindelse med overfladebehandlingen og der bør derfor altid udføres en prøve påføring på et mindre område.

Vurdering af overfladen.

Designgulve er håndlavede og man må forvente variationer i overfladen, ligesom at man skal være indstillet på, at reparationer og eftergang ikke kan udføres uden synlige overgange. Gulvbranchen har udarbejdet en række generelle retningslinjer til vurdering af gulvoverflader du kan finde dem ved at benytte dette link.

1.5.0.3 Kalciumsulfat baserede gulve

Kalciumsulfat er den fysisk/kemisk betegnelse for gips. Gulve udført i gips kræver montering af en eller anden form for topbelægning og gips anvendes derfor udelukkende til undergulve. Gips kan udlægges tørt i form af gulvplader eller udlægges vådt i form af afretningsmasser eller spartelmasser. I dette afsnit omtales gips udlagt som afretningsmasse. Gips udlagt som afretningsmasse kalds ofte for Anhydrit (om end det fysisk kemisk ikke er fuldstændig korrekt. Den kemiske betegnelse for gips er CaSO4-2H2O. Anhydritten fremkommer ved at gipsen fraspalter vandmolekylerne, hvorved der fremkommer et molekyle CaSO4 - processen forløber under varmeudvikling.)

Anhydritten har en række egenskaber der gør den attraktiv til afretning af råbeton o.lign.

• Den har gode flydeegenskaber

• Spændingsfattig

• Den har relativt gode lyddæmpningsegenskaber

• Den kan udlægges som "svømmende gulv" (min tykkelse ca. 35 mm. - produkt afhængigt)

Men som alle materialer har anhydritten også nogle begrænsninger. I modsætning til cement baserede afretningsmasser, der i et vist omfang bruger vandet i forbindelsen med hærdeprocessen, bruger anhydritten ikke vandet ved hærdningen. Vandet skal udskilles ved fordampning, hvilket gør at anhydritten generelt er længere udtørre, et forhold der er vigtigt at have fokus på i planlægningsfasen. Herudover skal man være opmærksom på at overfladen som regel kræver en grundig afslibning før den er klar til montering af topbelægninger.

Krav til arbejdsstedet

Undergulvet skal være stabilt, (ingen revner eller områder med skruk) og overfladen skal være ren, dvs fri for støv, olie, voks o.lign. Eventuelle huller og gennemføringer skal være lukkede. Bygningen skal være lukket (døre og vinduer skal være isat eller åbninger afdækket). De fleste producenter foreskriver at temperaturen på udlægningsstedet ikke må være under 5°C. Herudover anbefales det at området ventileres under og efter udlægningen. Vær også opmærksom på de fleste leverandøres vejleledende værdier for tørretider o.lign er opgivet ved en reference temperatur på 20°C og ca 50%RF. Ved lavere temperaturer og højere fugtighed er forløber udtørringsprocessen langsommere.

1.5.0.4 Magnesit gulve

Bindemidlet i magnesit er magnesiacement, der ved tilsætning af en klormagniumopløsning (vand og salt) hærder ved kontakt med luft. I magnesitgulve blandes magnesiacementen med forskellige organiske og uorganiske fyldstoffer samt farvestoffer. Ved at varierer sammensætningen af fyldstofferne kan man give magnesitten forskellige egenskaber. Magnesit til gulvbrug udlægges i våd tilstand ca. 20 mm. tykkelse. Gulvet er gangbart efter ca. 4-5 døgn, men har først opnået sin blivende styrke efter ca. 14 døgn (afhængigt af temperaturen og luftfugtigheden på arbejdsstedet). I forbindelse med hærdeprocessen udskiller gulvet en del vand. Gulvet bør derfor ikke tildækkes og lokalet bør ventileres, men vær opmærksom på at der ikke opstår træk, da dette kan medføre en uens udtørring, som igen vil føre til skader på gulvet. Efter afhærdning er overfladen forholdsvig ru og strukturere og vil ofte kræve en mekanisk efterbearbejdning. Før ibrugtagning skal overfladen efterbehandles. Til dette benyttes traditionelt en linolieblanding.

I våd tilstand magnesitblandingen særdeles reaktiv og dette kan medfører det tæring af jern, f.eks. vandrør. Kontroller derfor at der er en intakt isolering mellem magnesitten og eventuelle metaldele. Magnesitgulve er hårde at gå på, men ikke så kolde som betongulve. Gulvet har god skridsikkerhed, selv i våd tilstand. Materialet er skørt, og kan derfor ikke tåle slag eller anden overlast. Beskadiges et magnesitgulv, er det muligt at foretage en reparation, men den vil altid kunne ses. Arbejdet bør overlades til en fagmand. Mindre skader / revner kan eventuelt repareres med en egnet fugemasse.

Hvis magnesitten udtørrer, støver den. Magnesitgulve kræver derfor løbende vedligeholdelse. Den periodiske vedligeholdelse består af en afvaskning af gulvet i vand, tilsat sæbespåner. Herefter efterbehandles med en linolieblanding. Som dagligrengøring er støvsugning kombineret med leglighedsvis afvaskning som regel tilstrækkelig.

1.5.0.5 Asfalt baserede gulve

Fugefrie gulve af støbeasfalt benyttes især, hvor der stilles krav til hygiejne, slidstyrke, gangvenlighed eller kemiske belastninger. Støbeasfalt fremstilles af mineralske fyldstoffer som grus og kalk med asfaltbitumen som bindemiddel og udlægges ved en temperatur på 200 - 250°C på et damptrykudligningslag af alu-folie. Støbeasfalt er godkendt som klasse G gulvbelægning og kan udlægges på forskellige underlag, fx beton, cementstabiliseret grus og asfaltbærelag. Støbeasfalt har en meget høj vanddampmodstand og kan derfor anvendes på fugtigt underlag, herunder ny støbt beton. Da blandingens sammensætning kan varieres afhængigt af formålet, bør der inden endeligt valg indhentes specifikke oplysninger hos leverandøren. Støbeasfalt benyttes som færdigt gulv eller som undergulv for en anden gulvbelægning.

Gulvbelægning af støbeasfalt udlægges i ca. 25 mm. tykkelse og giver en fugefri tæt overflade med gode fysiske, kemiske og mekaniske egenskaber. Mindre ujævnheder i underlaget udfyldes ved udlægningen. Belægningen kan udføres i sort eller rødbrun farve, med glat eller ru overflade samt med forskellige former for overfladestruktur og friktionsegenskaber.

1.5.0.6 Hærdeplastgulve

Hærdeplastbaserede

Denne type af gulve kan underdeles i følgende hovedgrupper, ud fra en produkternes kemiske sammensætning og hærdningsproces

Acryl

Acryl er en hærdeplast, hvor bindemidlet er MMA (methylmetacrylat), som polymeriserer ved tilsætning af en hærder (initiator).

Epoxy

Epoxy er en hærdeplast, hvor bindemidlet er en lav- eller højmolekylær epoxyresin, som hærder ved tilsætning af en hærder komponent.

Polyuretan

Polyuretan er en hærdeplast, hvor bindemidlet er polyuretan (normalt præpolymeriseret), som hærder ved tilsætning af en hærdekomponent indeholdende isocyanat. Polyuretan leveres også som 1-komponent indeholdende isocyanat, der hærder ved hjælp af fugt. Fugefrie gulve baseret på hærdeplast benyttes især, hvor der stilles store krav til hygiejne, slidstyrke eller kemiske belastninger. Hærdeplaster er karakteriseret ved, at de hærder ved en kemisk reaktion og giver et slutprodukt med stor stabilitet overfor ydre påvirkninger. Gulve af hærdeplast leveres i mange varianter med hensyn til tykkelse og sammensætning. De udlægges normalt på cementbaseret underlag, men kan under særlige forhold også udlægges på træbaseret underlag og på underlag af stål eller asfalt. Gulve af gips (anhydrit) er ikke velegnede som underlag for hærdeplastgulve og må forud for udlægningen af hærdeplastgulvet spartles med en cementbaseret spartelmasse.

Valgt af belægningstype afhænger af de egenskaber, det færdige gulv skal have, og hvilke af disse gulvbelægningen skal bidrage til. Hvis belægningen fx skal bidrage væsentligt til at reducere punktbelastningen på underlaget, må der vælges en forholdsvis tyk belægningstype.

I det følgende gives en kortfattet oversigt over de gængse belægningstyper.

Støvbinding

• Støvbinding er en overfladebehandling af upigmenteret eller pigmenteret hærdeplast, som anvendes på gulve af cementbaserede materialer. Grundet sin evne til at trænge ind i underlaget forøges overfladens slidstyrke og kemikalieresistens samtidig med, at støvgenerne reduceres.

• Herud over findes der også en række en-komponente produkter som PVB (PolyVinylButyral) og vandglas.

Forsegling/coatning

• Forsegling/coatning er en lagdannende overfladebehandling, som normalt udføres i tykkelser op til 0,3 mm. Forsegling anvendes på gulve af cementbaserede materialer, hvor den følger overfladens planhedsvariationer. Støbeskel, revner og lignende vil forblive synlige.

• Forsegling anvendes i områder med moderat belastning, hvor den øger overfladens fysiske og kemiske egenskaber. Kan udføres pigmenteret eller upigmenteret.

Tyndfilm: 0,3 - 1 mm.

• Tyndfilm giver en overflade med en tykkelse fra 0,3 - 1 mm.

• Tyndfilmen følger overfladens planhedsvariationer. Små ujævnheder i overfladen udfyldes dog delvis.

• Tyndfilmen øger overfladens fysiske, kemiske og mekaniske egenskaber og giver en tæt og porefri gulvoverflade. Udføres sædvanligvis pigmenteret.

Belægning: Tykkelse 1-3 mm.

• Gulvbelægning af hærdeplast i tykkelser fra 1 - 3 mm. giver en tæt og porefri overflade, som øger gulvets fysiske, kemiske og mekaniske egenskaber.

• Belægningen følger underlagets planhedsvariationer. Mindre ujævnheder vil dog blive udfyldt. Udføres pigmenteret eller med indfarvet kvartssand samt med glat eller ru overflade.

Belægning: Tykkelse over 3 mm.

• Gulvbelægning af hærdeplast i tykkelser over 3 mm. giver en tæt og porefri overflade, som øger gulvets fysiske, kemiske og mekaniske egenskaber betydeligt.

• Belægningen følger underlagets planhedsvariationer. Lidt større ujævnheder vil dog blive udfyldt. Udføres pigmenteret eller med indfarvet kvartssand samt med glat eller ru overflade.

Ledende belægning

• Endvidere kan gulvmaterialer af hærdeplast leveres som ledende gulvbelægning med dokumentation for, at de opfylder kravene i fx engelske og tyske normer.

• Der må påregnes variationer mellem egenskaberne, afhængigt af materiale og produktsammensætning. Inden endeligt valg, bør der derfor indhentes specifikke oplysninger hos leverandøren.

Krav til arbejdsstedet

Underlagets styrke og overfladestruktur har afgørende betydning for en tilfredsstillende vedhæftning mellem gulvbelægning og beton. Overfladestyrken (sammenhængsstyrken) skal mindst være 1,8 MPa for industrigulve og mindst 1,5 MPa ved let industri. Overfladen skal være fri for slamlag, voks (curing-membran) samt spild af olie, fedt, og lign. urenheder.

For at opnå tilfredsstillende vedhæftning mellem underlag og gulvbelægning, vil det ofte være nødvendigt at foretage en mekanisk bearbejdning af underlagets overflade. Svage overfladelag i beton kan fjernes ved slyngrensning, diamantslibning eller fræsning. Metodevalg foretages ud fra de aktuelle forhold, fx i relation til støj, støv og fugt. Herudover skal man have et særligt fokus på eventuelle svindrevner og spartelslag, da de har en tendens til at kunne ses gennem den færdige belægning.

Underlaget skal have samme planhed, som kræves af det færdige gulv ( ± 2 mm på et 2 m retholt, med mindre andet er aftalt). Se mere i Sektionen om Valg af gulv. Fugtindholdet i nyudstøbte betondæk må højst være 85% RF.

I ældre terrændæk, kælderdæk og lign. kan der være opstigende grundfugt på grund af manglende fugtspærre i konstruktionen. Der bør derfor også i sådanne konstruktioner foretages fugtmåling, før der lægges gulv. Se sektionen Valg af gulv.

Under udlægning skal overflade- og rumtemperaturen være 15-25ºC og luftfugtigheden højst 85% RF. Dog skal overfladetemperaturen mindst være 3ºC over rummets dugpunkttemperatur. Eventuel gulvvarme skal være slukket i min 3 dage før postart. Vær opmærksom på at følge leverandørens anvisninger ved opstart af gulvvarmen.

Underlaget skal støvsuges, umiddelbart før gulvet lægges. I visse tilfælde anbefales en decideret grundrensning af gulvet.

Afhængigt af produkt kan gulvet benyttes til gangtrafik efter 2 - 24 timer efter sidste gang påføring. Fuld belastning er mulig efter 2 - 7 døgn.

Nylagte gulve af hærdeplast er sårbare og kan ødelægges, hvis de benyttes som arbejdsgulv for andre håndværksfag. Det anbefales derfor, at der allerede under byggeriets planlægning tages stilling til, om tidsplanen nødvendiggør afdækning af færdige gulvoverflader.

1.5.0.7 Hulkeler – hærdeplastgulve

Hærdeplastgulve kan i vandbelastede områder med fordel afsluttes med hulkeler mod vægge o. lign. I øvrige områder anbefales afslutningen udført med almindelige fodpaneler eller lister i træ, plast, gummi. Hulkeler kan enten udføres ved at monterer præfabrikerede hulkeler langs væggene eller de kan håndlaves i epoxymørtel. Begge metoder har fordele og ulemper. På figur 1 og 2 er vist et eksempler på de to typer.

Fig. 1: Eksempler på præfabrikerede hulkeler

Fig. 1: Eksempler på præfabrikerede hulkeler

De faste hulkeler leveres i længder på ca. 1 meter og limes til gulv og væg med en dertil egnet monteringslim, ofte anvendes et epoxybaseret produkt. De fås i forskellige udformninger (højder, bredder og rundingsradier), typiske højde/bredde forhold er 50/25 eller 100/25. De kan tilpasses på længden ved brug af en almindeling geringssav, men tilpasses kun vanskeligt i højden. Der kommer samlinger for hver ca. 1 meter. Samlingerne vil være synlige. De faste hulkelslister stiller store krav til tolerancerne på gulve og vægge. Er væggene skæve, gulvene ikke plane og vinklen mellem gulv og væg ikke ret, vil listerne "springe " i samlingerne og der kan komme mellemrum mellem listerne og væggene/ gulvet. Disse må efterfølgende fuges eller lukkes på anden vis.

Fig. 2: Eksempel på en hulkel udført i epoxymørtel

Fig. 2: Eksempel på en hulkel udført i epoxymørtel

Håndlavede hulkeler udført i epoxymørtel er langt mere fleksible, men man må, for disse, forvente langt større udsving i overflader og rundingsradier.

Rundingen i mellem gulv og væg kan udføres ved brug af et hulkelsjern og man er som bygherre begrænset af de radier, som jernene leveres i. Den håndlavede hulkel kan i princippet tilpasses til opgaven idet den følger forløbet af gulv og væg, hvilket gør denne type af hulkel meget anvendelig. Højden anbefales begrænset til 75 mm. Hulkeler højere end 75 mm. har en tendens til at "falde sammen" i hærdeperioden og danne "gardiner". I forbindelse med flisearbejder bør nederste fliserække overlappe hulkelen, således at vand der løber ned af væggen ikke kan løbe ned bag hulkelen. Overfladen og højden på epoxyhulkeler afhænger af epoxymørtlen. Ønsker man en "høj" hulkel, skal denne opbygges / støbes over flere omgange og der skal afsættes tid til dette. Indvendige og udvendige hjørner, vil aldrig kunne fremstå 100% skarpe og rene. De er håndlavede og vil variere. Ved større entrepriser er det en god ide, at udføre en muck-up, således at løsninger og forventninger kan afstemmes.

1.5.0.8 Afslutning mod gulvafløb

Overgangen mellem hærdeplastgulvet og afløbsrender er et meget kritiske område.

Særlig fokus kræver dette område, hvis afløbet bliver udsat for store temperatursvingninger, som fx i industrikøkkener og i fødevareindustrien.

Temperatursvingningerne forekommer når fx kogende vand hældes direkte i afløbet eller i forbindelse med rengøring af lokalerne, hvor man ofte anvender varmvandspuling. Temperaturstigningen vil få afløbet til at udvide sig. En temperaturstigning på 50°C i en 3 meter lang rende vil forårsage en længdeudvidelse på 2-3 mm. (afhængig af det konkrete materiale). Når afløbsrenden og gulvet skal bygges sammen, er det vigtigt, at man er opmærksom på dette forhold, og at ovegangen udformes så den kan optage bevægelserne.

Der findes en lang række afløb, der er specielt designet til hærdeplastgulve. Gulvbranchen anbefaler, at man ved valg af afløbskonstruktion nøje overvejer, hvilke påvirkninger afløb og gulv forventes at blive udsat for. Forventes konstruktionen at blive udsat for store temperatursvingninger, anbefaler Gulvbranchen, at der udføres en elastisk fuge i overgangen mellem afløbet og gulvbelægningen. Ved valg af fugemateriale bør påvirkninger fra temperaturer, rengøringsmidler og andre kemikalier indgå i beslutningsgrundlaget. Fugen bør være ca. 10 mm. bred og 6-7 mm. dyb. Det er vigtigt, at fugeleverandørens anvisninger følges omhyggeligt. Siderne i fugerillen bør primes og der bør anvendes fugebund. Fuger omkring industriafløb bør efterses 2-3 gange om året. Udsættes de for store termiske og kemiske påvirkninger, må man forvente en kort levetid (1-2 år).

For at sikre en god forankring af hærdeplastbelægningen anbefaler Gulvbranchen at der udføres rille/recesses omkring afløbskanten. Rillen skal være så stor (bredde og dybde) at hærdeplastbelægningen omslutter fugen, se nedenstående billeder.

Fig. 1a

Fig. 1a  Fig. 1b

Fig. 1b

Figur 1 a & b: Afslutning af hærdeplastgulve mod afløbsrende, Billed Blucher.

1.5.0.9 Skridhæmmende overflader

Gulvbelægninger af hærdeplast kan gøres skridhæmmende ved at tilsætte hårde partikler til basismaterialet, typisk anvendes sand eller glasperler. Størrelsen, mængden og formen af sandkornene samt forholdet mellem sand og basis-materiale vil være bestemmende for overfladen på gulvet, og dermed hvor skridhæmmende gulvet bliver. Påføres gulvet en topcoat vil tykkelsen af denne også påvirke resultatet. De grundlæggende principper i opbygningen af skrid hæmmende epoxy og polyuretan gulve er de samme som for almindelige PU- / epoxygulve.

Den første proces er typisk en primning af undergulv. Næste operation er påføring af en den egentlige belægning også kaldet bodycoaten. Mens bodycoaten er våd afsandes gulvet. Afsandingen udføres manuelt og man må som bygherre forvente (store) variationer i overfladen. Udlæggeren skal selvfølgelig have en fornærmelse for, hvor meget sand der strøs i pr. m², men variationer vil forekomme. De bedste resultater fås som regel, ved at lave en "mætning" af bodycoaten, d.v.s. at bodyen tilsættes så meget sand, at der efter afsandningen ligger et ensartet jævnt fordelt lag sand over hele gulvfladen. Det overskydende sand fjernes, når gulvet er hærdet ved støvsugning el.lign. Gulvet vil nu have en meget grov og ru overflade og ofte være for skridhæmmende og mere eller mindre umuligt at renholde. (Men som tidligere nævnt, vil overfladen også afhænge af kornstørrelsen og formen på det sand, der er anvendt). For at gøre overfladen mere glat udføres der derfor ofte en let afslibning af overfladen. Sluttelig kan gulvet på føres en topcoat.

Det er også muligt, at tilsætte de skrid hæmmende partikler i topcoaten, ved denne metode, er det typisk glasperler der tilsættes. Ved denne metode kan der kun opnås en relativ let skridsikring og man skal som forbruger være opmærksom på, at skridsikringen vil aftage over tid primært p.g.a. slid, men forkert / for meget brug af rengøringsmidler vil også påvirke overfladen. For de opsandede produkter er skridsikringen mere stabil overtid.

Lav altid et prøve gulv. De fleste leverandører oplyser i deres tekniske specifikationer, hvilken skridsikkerhedsklasse belægningen tilhøre, men små variationer i mængder og materialer kan give store variationer i den færdige oveflade. Forventningerne til det færdige gulve bør derfor altid afstemmes mellem entreprenør og bygherre ved, at der udføres et prøve areal til bygherres godkendelse.

1.5.0.10 Valg af fugefri gulvbelægning

Valg af korrekt gulvkonstruktion kan opnås ved en analyse af de belastninger, gulvbelægningen vil blive udsat for. Såvel konstruktionens bærende del som gulvbelægningen skal vælges korrekt i forhold til de statiske, dynamiske, kemiske og termiske påvirkninger, som konstruktionen udsættes for.

Statiske, dynamiske, kemiske og termiske påvirkninger under udførelse og drift, herunder rengøring, skal tages i betragtning ved valg af gulvkonstruktion.

Det skal understreges, at gulvet altid kun er lige så godt som det undergulv, det lægges på, dvs. betondækket eller et evt. afretningslag.

Statiske og dynamiske belastninger

• Punktlast

• Belastninger fra reolben, stillestående hjul eller lign. med cirkulære, rektangulære eller kvadratiske trykflader under 225 mm².

Linjelast

• Belastninger fra stive, gennemgående (rektangulære) trykflader med maksimal belastningsbredde på 100 mm.

Fladelast

• Belastninger fra maskiner, apparatur eller lign. med cirkulære, rektangulære eller kvadratiske trykflader over 225 mm².

Vibrationer

• Vibrationer fra maskiner eller andet, der kan forårsage svingning i konstruktionen og på længere sigt resultere i materialebrud. Ganglast Hvor der forekommer intensiv ganglast, fx i smalle gangarealer og lign., skal den medtages i vurderingen af belastningerne.

Hjullast

• Hjul på kontorstole har en lille diameter og udsætter derfor gulvet for en stor punktbelastning.

• Trykfladen fra støbte jern- og nylonhjul (hjulets faktiske berøringsflade) er ofte meget lille - under 1 cm². Dette kan give uacceptabelt store belastningsoverførsler til gulvet. Når hjulene kører, sker der desuden en kraftig mekanisk påvirkning af gulvet.

Kemiske belastninger

• Det er vigtigt at kunne vurdere, om der er risiko for kemiske påvirkninger af en gulvbelægning. For at kunne foretage denne vurdering, kræves der detaljerede oplysninger om hvilke stoffer, gulvbelægningen kan komme i kontakt med - og hvordan!

• Det er fx ikke tilstrækkeligt at vide, at materialet kommer i kontakt med syre, da dette er et vidt begreb. Typen, pHværdien, koncentrationen og en eventuel kombination af forskellige påvirkninger, fx syre i forbindelse med varme, har afgørende betydning for den endelige vurdering af en konkret gulvbelægnings modstandsevne.

• Ud over at vurdere individuelle kemikaliers virkning på gulvet, skal konsekvenserne af eventuelle kemiske reaktioner også tages med i overvejelserne. Hvad sker der fx, hvis kemikalierne blandes på gulvet? Hvad er deres koncentration eller opløsning, både i det øjeblik de tabes - og efter fordampning?

Termiske belastninger

• Permanent høje eller lave temperaturer og skiftende temperaturer (temperatur chok) kan være årsag til svigt i gulvbelægningen.

• Ud over at tage hensyn til temperaturer på maskinudstyr i drift og produkter under bearbejdning, skal der også tages hensyn til temperaturer i tilstødende områder. I visse områder, hvor der fx udføres autoklavering, kogning, sterilisering eller lynfrysning, er temperaturerne ofte ekstreme.

Sikkerhed / komfort

Gangsikkerhed

• I gang- og arbejdsområder kræves forskellige grader af gangsikkerhed, afhængigt af om gulvet er vådt eller tørt.

• Derfor bør gulvets overfladefinish afstemmes med risikoen for spild på gulvet. For våde gulve gælder, at jo grovere overfladestruktur - jo større gangsikkerhed. Modsat bliver kravene til rengøring og hygiejne sværere at opfylde.

• Det tilrådes derfor at udføre gulvet med forskellig gangsikkerhed, der er afstemt, så kravene for specifikke områder kan honoreres.

Hygiejne

• I mange virksomheder, fx medicinalindustrien, kosmetikindustrien, fødevare-, drikkevareindustrien, samt kemiog elektronikindustrien, stilles der strenge krav til hygiejnen.

• Kravet vil normalt være helt rene omgivelser, det vil fx sige støvfrie gulve uden revner eller skarpe vinkler, der er vanskelige at rengøre.

Elektrostatiske egenskaber

• I mange industrier stilles der krav til gulvets elektrostatiske egenskaber.

• Kravet stilles bl.a. for at forebygge elektriske forstyrrelser i følsomt elektronisk udstyr eller for at modvirke ophobning af statisk elektricitet, som kan medføre gnistdannelse eller eksplosionsfare.

Valg af gulvbelægning

• Valg af fugefri gulvbelægning bør altid foretages ud fra funktionskrav, som er opstillet på baggrund af funktionsanalyser.

• Til dette formål udarbejdes et brugs- og/eller produktionsflow og en komplet rumliste for byggeriet. Dernæst udføres en funktionsanalyse for gulvet i de enkelte rum, fx ved at benytte skemaet "Valg af fugefri gulvbelægning - funktionsanalyse".

• Resultatet af funktionsanalysen udgør en oversigt over de belastningsgivende funktionskrav og er dermed grundlaget for korrekt valg af gulvbelægning og konstruktionsopbygning.

Leverandører af fugefrie gulve kan på baggrund af funktionsanalysen rådgive om hvilke produkt- og belægningstyper, der er mest velegnede til et givet formål.

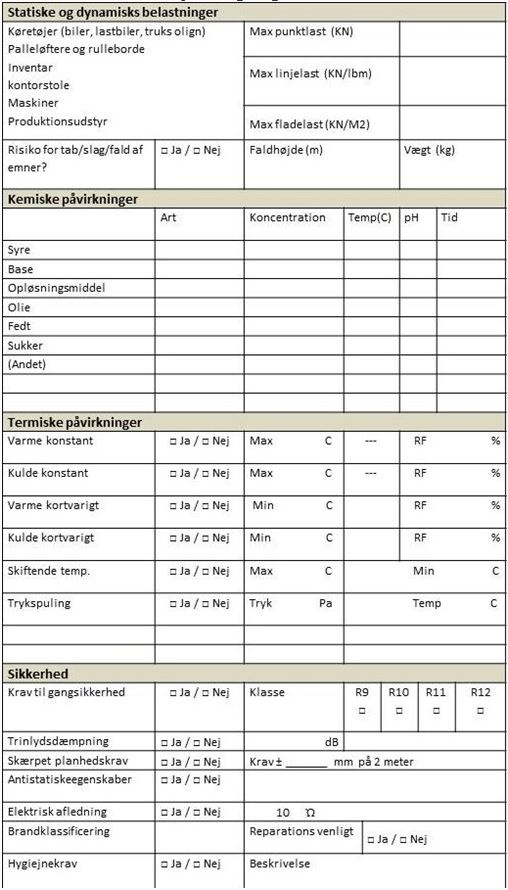

1.5.0.11 Funktionsanalyse - fugefrigulve

Funktionsanalyse 1

Funktionsanalyse 1

1.5.0.12 Rengøring

Rengøring af fugefri gulvbelægninger er beskrevet i kapitlet om vedligeholdelse, gå til afsnittet ved at benytte dette link.

1.5.0.13 Forventninger til hærdeplastgulve

Vores oplevelse af et produkt er i meget høj grad styret af de forventninger vi har til det. Gulvbranchen har udarbejdet en folder, der adresserer de forventninger du som forbruger med rette kan have til et hærdeplastgulv, klik her for at læse forventningsfolderen. Herudover findes der på www.gulvbranchen.dk en række tekniske publikationer om gulve og gulvbelægninger. Ved at klikke her, vil du blive dirregeret videre til de tekniske publikationer.