- Forside

- Gode råd om gulv

- Konstruktioner

- Undergulve

- Pladeundergulve

- Akustikpaneler

- Afpassede tæpper

- Bambusgulve

- Bordplader & bordben

- Designgulve

- Fliser og klinker

- BeefEater gasgrill

- Gode råd om gulv

- Gulvtæpper

- Gulvvarme

- Græstæpper

- Korkgulve

- Køkken, bad & garderobe

- Laminatgulve

- Linoleumsgulve

- Maling, Væv & Spartel

- Måtter

- Møbler & Boliginteriør

- Nålefilt og messetæpper

- Plejeprodukter

- Restpartier & gode tilbud

- Sildebensparket & Stavparket

- Tæppefliser

- Terrassebrædder

- Tilbehør

- Trægulve

- Vareprøver

- Vinylgulv

- Værktøj

- Øvrige produkter

- Loft- og vægpaneler

- Flotte gulve

- Fyrretræsgulv

- Klikgulve

- Bestilte varer

-

-26%

-

Populær29,00 DKK

-

Populær21,00 DKK

-

29,00 DKK pr m2

-

29,00 DKK pr m2

Pladeundergulve

Alle informationer på denne side er kopieret materiale fra Gulvfakta som er et fagteknisk opslagsmateriale, Kilde: Gulvfakta

Pladeundergulve er karakteriseret ved at de opbygges at mindre enheder der samles på arbejdsstedet (fx gulvspånplader, eller brædder/blændgulve)

2.1.1.1 Materialer til gulvunderlag

2.1.1.2 Vigtige egenskaber for undergulve

2.1.1.3 Pladematerialer

2.1.1.4 Træbaserede plader generelt

2.1.1.5 Gulvspånplader

2.1.1.6 Krydsfiner

2.1.1.7 Træfiberplader

2.1.1.8 Gipsplader

2.1.1.9 Lægningsmetoder

2.1.1.10 Underlag, mellemlag mv.

2.1.1.11 Dilatationsfuger

2.1.1.12 Strøkonstruktioner

Alle informationer på denne side er kopieret materiale fra Gulvfakta som er et fagteknisk opslagsmateriale, Kilde: Gulvfakta

2.1.1.1 Materialer til gulvunderlag

I dette afsnit behandles undergulve af pladematerialer, fx spånplader, træfiberplader og gipsplader. Både undergulve udført som bærende undergulve og som svømmende undergulve omtales. De strøkonstruktioner, der omtales i dette kapitel, er beregnet til brug sammen med pladematerialer. For strøkonstruktioner til trægulve henvises der til afsnittet om trægulve.

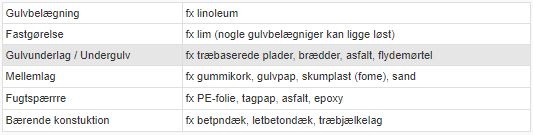

Figur 1. Gulvunderlagets placering i gulvkonstruktionen.

Lim og tilhørende primer til klæbning af gulvbelægninger mod undergulvet er behandlet i et selvstændigt kapitel.

Udførelse af undergulv bør i størst muligt omfang indgå i gulventreprenørens entreprise således, at ansvaret for udførelsen med hensyn til konstruktionens udseende og brugsegenskaber er placeret det samme sted.

Materialer til gulvunderlag

Som det ses af figur 1, kan undergulvet bestå af flere lag. Der vil dog langt fra altid være brug for dem alle. Desuden kan rækkefølgen variere afhængigt af den aktuelle opbygning. Nogle af de mange materialer, der anvendes, kan endvidere tjene flere formål (have flere funktioner), sand kan fx både fungere som afretningslag og som mellemlag i svømmende konstruktioner.

To hovedgrupper af pladebaserede undergulve er:

Massivt opbyggede konstruktioner, hvor der er fysisk sammenhæng mellem de enkelte lag i konstruktionen.

Eksempel:

• Træbaserede plader på træbjælkelag.

Svømmende konstruktioner, hvor gulvet kan bevæge sig uafhængigt af det bærende underlag.

Eksempel:

• Afrettet etagedæk med plastfolie, hvorpå der er udlagt træbaserede plader.

Svømmende pladegulve anvendes ofte, hvor der er behov for hurtig og tør afretning af et etagedæk. I det følgende gives en kort gennemgang af de vigtigste egenskaber for de lag, som kan indgå i et gulvunderlag. Desuden gives der eksempler på en række almindeligt anvendte produkter inklusive alment tilgængelige materialeoplysninger. Det er undergulvet, der er grundlaget for det færdige gulvs brugsegenskaber, fx med hensyn til:

Styrke - der bør vælges afhængigt af brug.

Planhed - krav til afretning.

Fugt - konstruktiv opbygning, fugtspærring.

Lyd og gang - eftergivelighed af mellemlaget.

Levetid - materialevalg, design, brug.

2.1.1.2 Vigtige egenskaber for undergulve

For at den samlede gulvkonstruktion skal fungere som ønsket, skal der være en samvirken mellem gulvbelægningen og dens undergulv og desuden med omgivelserne, fx den bærende konstruktion, underliggende terræn eller omgivende vægge. Det er derfor nødvendigt, at underlaget har en række egenskaber, som dels afhænger af den aktuelle gulvbelægning, dels af bygningsfysiske krav til hele gulvkonstruktionen.

Ved valg af gulvunderlag skal der bl.a. tages stilling til:

Krav til styrke af undergulvet, fx til plademateriale. Ønsker til planhed af underlag/færdigt gulv herunder behovet for afretning og spartling.

Behovet for fugtspærre. Krav til styrke og elasticitet af mellemlaget, i afhængighed af forudsete belastninger og ønsker til lydreduktion.

De nødvendige egenskaber er ikke de samme for alle gulvunderlag. I det følgende omtales kortfattet nogle af de egenskaber for gulvunderlag, som især kan være vigtige:

Bæreevne

Gulvunderlaget skal være i stand til at overføre de belastninger, der kan forventes ved den fremtidige brug, uden at der opstår uønskede deformationer eller skader.

Styrke og stivhed/elasticitet

Undergulvet skal kunne modstå de statiske og dynamiske belastninger, fx fra nyttelast, møbler, personer og rullende færdsel, som normalt må forventes at forekomme ved den påtænkte brug. Af hensyn til gangbehagelighed kan en vis eftergivelighed (elasticitet) være ønskelig, mens der på den anden side ikke må ske for store deformationer på grund af almindelig last under brug.

Planhed

Undergulvet skal være så plant, at gulvet kan opnå den ønskede planhed. For tynde gulvbelægninger og ikkebærende trægulve betyder dette, at undergulvet skal kunne udlægges med samme planhed, som der ønskes af det færdige gulv, se mere om dette i afsnittet om planhed.

Højdeudjævnende

Undergulvet skal være i stand til at optage mindre højdeforskelle i den underliggende bærende konstruktion.

Fugtspærrende virkning

For at mindske risikoen for skader på grund af fugttransport nedefra, fx på grund af byggefugt, kan det være nødvendigt at forsyne gulvkonstruktionen med en fugtspærre, se mere i afsnittet om byggefugt.

Stabilitet overfor fugt

Gulvet må ikke få skadelige deformationer på grund af fugtpåvirkninger, der skyldes normal brug.

Lydtekniske egenskaber

Undergulvet skal have sådanne lydtekniske egenskaber, at det kan medvirke til at reducere transmission af luftlyd og trinlyd, se mere i afsnittet om lyd og gulve.

Varmebestandighed

Gulvmaterialer, der skal benyttes i forbindelse med gulvvarmeanlæg, skal kunne tåle de temperaturer, der kan forventes at optræde i den aktuelle konstruktion.

Varmeisolerende virkning

Undergulvet skal medvirke til varmeisoleringen af dækkonstruktionen.

Levetid

Undergulvet skal bibeholde sine egenskaber i tilfredsstillende omfang i en længere årrække udsat for normale nedbrydningsfaktorer, fx fugt eller fysiske spændinger fra brugen.

2.1.1.3 Pladematerialer

Pladematerialer er i denne omtale forudsat anvendt i svømmende gulve eller bærende gulve.

Tynde spån- og træfiberplader kan tillige benyttes til opretning af gamle bræddegulve mv.

Pladematerialer til undergulve kan være:

• Spånplader (inklusive OSB-plader)

• Krydsfinerplader • Gipsplader

• Træfiberplader (incl. MDF-plader)

Feltstørrelser

Undergulve af plader må opdeles i felter med dilatationsfuger, som skal videreføres igennem gulvbelægningen. Feltstørrelsernes udstrækning bør for svømmende gulve normalt ikke overstige 8 -10 meter afhængigt af pladetype. Ved større feltstørrelser må der søges rådgivning hos pladeleverandøren. Antal og placering af fuger er bestemt af gulvets konstruktive opbygning herunder pladetypen, belastningen, de forventede fugtvariationer og rummets geometri. Store mekaniske belastninger, fx fra tunge møbler eller inventar, kan hindre bevægelsesmulighederne og kan nødvendiggøre, at feltstørrelserne reduceres.

Fuger

Dilatationsfuger i den bærende konstruktion skal altid føres igennem gulvkonstruktionen inklusive gulvbelægningen. I svømmende gulve kan der være behov for yderligere fuger afhængigt af konstruktionsopbygning, gulvets geometri og belastningen. Yderligere oplysninger om fuger i gulve findes i "Fugemappen" udgivet af Fugebranchens Samarbejds- og Oplysningsråd (FSO).

2.1.1.4 Træbaserede plader generelt

Spånplader, krydsfinerplader, træfiberplader og lignende plader, der benyttes i gulvkonstruktioner i byggeriet, skal være CE-mærket. Det er pladeproducenten eller den forhandler, der selv importerer pladerne, der er ansvarlig for CE-mærkningen. Den harmoniserede standard DS/EN 13986, der ligger til grund for CE-mærkningen, gælder for produktion og anvendelse i Europa. Som tillæg til standarden er der udarbejdet nationale bestemmelser i det omfang, der er nødvendigt for at overholde byggelovgivningen - en såkaldt NA (National Application). I den danske NA er der krav om, at de CE-mærkede træplader skal overholde formaldehydklasse E1 og at gulvplader til bærende formål desuden skal overholde særlige krav til styrke og stivhed for punktlast og dynamisk last, som svarer til de hidtidige NKB-regler. CE-mærkningen af træbaserede plader vil derfor indeholde følgende oplysninger i afhængighed af, om pladen kan benyttes til bærende undergulv eller kun må benyttes til svømmende undergulv, dvs. fuldt understøttet undergulv.

Fugtforhold

Træbaserede plader skal leveres med et fugtindhold i intervallet 8 ± 2 % (vægtprocent). Fugtspærre skal anvendes, hvis der er risiko for fugtpåvirkning fra underlaget. På grund af træbaserede pladers svind og kvældning som følge af fugtvariationer, skal der sikres bevægelsesmulighed i form af en fuge langs vægge og ved gennembrydninger i gulvfladen. Fugens bredde afhænger bl.a. af pladetype og gulvfladens størrelse.

Udførelsesstedet

For at undgå unødig opfugtning bør lægningen ske så sent i byggeprocessen som muligt. Før lægningen skal bygningen være lukket og tør, og der skal være sat varme på bygningen. Arbejder, der kan tilføre bygningen større mængder fugt, fx murerarbejde og grundlæggende malerarbejde, bør være afsluttet.

Lokaler, hvori der skal udlægges træbaserede plader, skal være i ligevægt med en for årstiden normal luftfugtighed, dvs. 35-65% relativ luftfugtighed ved ca. 20°C.

2.1.1.5 Gulvspånplader

Gulvspånplader er forsynet med fer og not på alle fire sider. Til renovering og svømmende gulvkonstruktioner i boliger anvendes gulvspånplader i tykkelser ned til 12 mm. Ved større belastninger end i boliger, fx i erhvervs- og samlingslokaler, bør tykkelsen dog mindst være 16 mm.

Overfladen på spånplader udgør et "bedre" underlag til gulvbelægning end krydsfiner, da den er mere jævn og ensartet.

Pladerne sammenlimes i fer og not med PVAc-lim eller lignende.

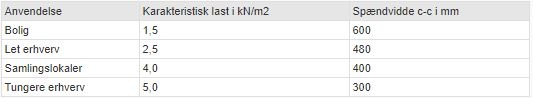

Tabel 1. Maksimale spændvidder for bærende undergulve af 22 mm spånplade. Spånpladerne skal være godkendt af Træpladekontrollen og kontrolmærket af fabrikken.

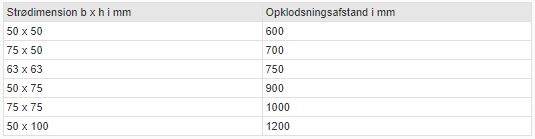

Tabel 2. Opklodsningsafstande og strødimensioner for pladegulve til brug i boliger.

Limningsklassen for gulvspånplader skal afpasses efter fugtforholdene i det rum, hvor pladerne skal anvendes. I fugtklasse I (almindeligt indeklima i opvarmede lokaler) anvendes limklasse V20, og i fugtklasse IU (uopvarmede rum eller rum med moderat fugtbelastning) anvendes limklasse V100 eller V313. Undergulve af spånplader bør kun anvendes som arbejdsunderlag for efterfølgende håndværkere efter omhyggelig afdækning. Yderligere information om spånplader kan fås i TRÆ 60 "Træplader" fra Træinformation.

2.1.1.6 Krydsfiner

Til svømmende gulvkonstruktioner anvendes gulvkrydsfiner, der fås i tykkelser ned til 14,5 mm. Krydsfinerplader til gulve er normalt forsynet med (godkendt) fer og not i de lange sider. Til svømmende gulve er det afgørende, at pladerne ikke er vindskæve. Der bør anvendes plader med mindst fem lag finer. Dækfinerens kvalitet er ved anvendelse af tynde gulvbelægninger afgørende for udseendet af det færdige gulv. Til dette formål bør der benyttes særlige pudsede eller letpudsede krydsfinerplader med jævn overflade, hvor alle huller og revner er udproppede eller fyldte. Alternativt kan der udlægges en overplade, fx en spånplade eller hård træfiberplade. Plader limes sammen med PVAc-lim. For yderligere information om krydsfiner henvises til TRÆ 60 "Træplader" fra Træinformation.

2.1.1.7 Træfiberplader

HDF og HB, dvs. plader med en densitet på mindst 900 kg/m3, i tykkelser mellem 3 og 9 mm anvendes som underlag for gulvbelægning. Til opretning af gamle bræddegulve etc. bruges hårde træfiberplader i tykkelsen 3-4 mm, som sømmes til underlaget. Til svømmende gulve benyttes plader i tykkelsen 6-9 mm forsynet med fer og not eller falset på alle 4 sider. Pladerne skal akklimatiseres i det rum, hvori de skal udlægges. Pladerne sammenlimes med PVAc-lim. Pladesamlinger forskydes mindst 300 mm. Plader skal renskæres langs alle begrænsninger. Normalt frarådes det at anvende falsede træfiberplader i rum over ca. 25 m2. Yderligere information om træfiberplader kan fås i TRÆ 60 "Træplader" fra Træinformation.

2.1.1.8 Gipsplader

Gipsplader til gulve kan enten være gipskartonplader eller fibergipsplader. Gipskartonplader kan udlægges i 19 eller 25 mm tykkelse. De kan leveres som specielle gulvplader forsynet med fer og not langs alle kanter eller som almindelige plader i 600 mm bredde, der udlægges i to lag med forskudte samlinger. Densiteten af gipskartonplader til gulve er ca. 1100 kg/m3. Gulvgipsplader er armeret med cellulosefibre. Fibergips til gulve leveres som gulvelementer, der består af fibergipsplader, der er sammenlimet forskudt for hinanden, så der fremkommer en fals langs kanterne. Densiteten er ca. dobbelt så høj som for træbaserede plader, hvilket gør gipsplader velegnede til dæmpning af luftlyd. Før pålægning af tynde tæppebelægninger eller halvhårde gulvbelægninger skal gipspladerne fuldspartles med en lagtykkelse på ca. 2 mm. Ved tykkere gulvbelægninger er spartling af pladesamlingerne tilstrækkelig. Gipsplader har meget små fugtbetingede bevægelser og kan endvidere anvendes i forbindelse med gulvvarme, da de tåler temperaturer op til 40°C.

2.1.1.9 Lægningsmetoder

Svømmende undergulve

Svømmende undergulve af plader kan bevæge sig frit i forhold til det bærende underlag, når pladerne svinder eller kvælder (udvider sig).

Der indlægges normalt et mellemlag mellem det bærende underlag og undergulvet, så der er sikkerhed for, at gulvfladen kan bevæge sig frit. Mellemlaget kan udføres af materialer, der bidrager til at forbedre varmeisoleringen og de lydmæssige egenskaber. Pladelagets og mellemlagets stivhedsegenskaber må vælges afhængigt af pladetypen og den forventede belastning. Svømmende gulve anvendes ofte, hvor der er behov for hurtig og tør afretning af et dæk. Hvis mellemlaget er udført af elastiske materialer, kan gulvfladen fjedre ved gang, hvilket gør gulvet behageligt at gå på. Store mekaniske belastninger, fx fra tunge reoler, punktlaster og skranker, kan hindre gulvets bevægelsesmuligheder. Ved gulve med uregelmæssig geometri og hvor der er søjler gennem gulvfladen, må gulvets frie bevægelsesmuligheder ikke hindres. Opdeles gulvfladen, bør det så vidt muligt ske i rektangulære felter, så de forventede bevægelser i begge retninger er nogenlunde ens.

Checkliste ved lægning af svømmende pladegulve:

• Den relative luftfugtighed i bygningen skal være mellem 35 og 65 %, afhængigt af årstiden, og temperaturen ca. 20°C.

• Bygningen skal være lukket, og varmeanlæg skal være installeret og i brug.

• Fugtindholdet i beton, letbeton mv. skal være i ligevægt med den for årstiden normale relative fugtighed, dvs. porefugtindholdet skal være på 35- 65 % RF. For beton- eller letbetonelementer vil det tage mindst et par måneder, før ligevægt er opnået. For beton støbt på stedet må der påregnes endnu længere tid.

• Isoleringsmaterialer mv. skal være tørre.

• Fugtspærre, fx i form af en 0,15 mm polyethylenfolie, skal være udlagt inden lægningen af gulvet til beskyttelse mod opfugtning fra byggefugt.

• Træbaserede pladematerialer skal have et fugtindhold på 8 ± 2 %.

• Lim, fugemasse og andre hjælpematerialer bør temperaturmæssigt akklimatiseres i mindst et døgn før brug, fx ved opbevaring i de rum, hvori de skal bruges.

Bærende gulve

Ved bærende pladegulve forstås gulve, som hviler på en lineær understøtning af strøer eller bjælker. Belastningen af gulvet overføres gennem pladerne til de underliggende strøer eller bjælker. Strøer opklodses på en underliggende konstruktion af fx beton eller letbeton, så der opnås et plant underlag for pladegulvet.

Bjælker indgår i træbjælkelag over krybekældre og i etageadskillelser. Både strøer og træbjælkelag giver gode muligheder for at anbringe lyd- og varmeisolerende materialer i hulrummet under undergulvet. Hulrummet kan desuden benyttes til fremføring af varme-, vand- og elinstallationer.

Bærende pladegulve kan udføres af spånplader eller krydsfiner.

Checkliste ved lægning af bærende pladegulve:

• Den relative luftfugtighed i bygningen skal være mellem 35 og 65 %, afhængigt af årstiden, og temperaturen ca. 20°C.

• Bygningen skal være lukket, og varmeanlæg skal være installeret og i brug.

• Fugtindholdet i beton, letbeton mv. skal være i ligevægt med den for årstiden normale relative fugtighed, dvs. porefugtindholdet skal være på 35- 65 % RF. For beton- eller letbetonelementer vil det tage mindst et par måneder, før ligevægt er opnået. For beton støbt på stedet må der påregnes endnu længere tid.

• Isoleringsmaterialer mv. skal være tørre.

• Opklodsninger udført med beton skal være hærdede og tørre.

• Fugtspærre, fx i form af en 0,15 mm polyethylenfolie, skal være udlagt inden lægningen af gulvet til beskytelse mod opfugtning fra byggefugt.

• Pladematerialer skal have et fugtindhold på 8 ± 2 %.

• Trægulvmaterialer tørret til brugsforholdene bør ikke pakkes ud før lægning.

• Fugtindholdet i træbjælker og strøer bør svare til pladernes. Gennemsnitsfugtindholdet bør højst være 12 % for strøer og 13 % for bjælker, og ingen enkeltmålinger bør være over henholdsvis 14 og 15 %.

• Lim, fugemasse og andre hjælpematerialer bør temperaturmæssigt akklimatiseres i mindst et døgn før brug, fx. ved opbevaring i de rum, hvori de skal bruges.

2.1.1.10 Underlag, mellemlag mv.

Fugtspærre

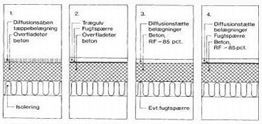

Før gulvbelægning monteres skal underlaget enten være tilstrækkeligt tørt, eller også skal der tages forholdsregler til beskyttelse af gulvet mod fugt, hvilket normalt sker ved anvendelse af en fugtspærre. Fugtspærre anvendes især ved beton, hvis det ønskes at undgå den lange udtørringstid, der kan andrage mange måneder, fx ca. 6 mdr. for en 100 mm beton 25 med ensidig udtørring. Behovet for anvendelse af fugtspærre er skematisk vist på figur 4, der stammer fra SBI-anvisning 178 "Bygningers fugtisolering", se endvidere i Gulvfaktas afsnit Teknik og kvalitet for yderligere informationer om byggefugt og fugtmålinger i betondæk.

Betegnelsen fugtspærre er anvendt her i lighed med anvendelsen i SBI's anvisninger og i TRÆ 41 "Lægning af trægulve".

Termen dampspærre anvendes i andre forbindelser, hvor fugttransport kun sker i dampform, fx i vægge og tage.

Enheden Z-værdi benyttes for diffusionsmodstandstal i stedet for det tidligere anvendte PAM. PAM-værdier omsættes til Z-værdier ved at dividere med to, fx har et materiale med en PAM-værdi på 100 en Z-værdi på 50.

Figur 4. Terrændæk i opvarmede bygninger. Fugtfølsomme gulbelægninger på beton.

1. Diffusionsåben gulvbelægning, fx tæppe uden tæt gummibagside. Betonen overfladetør.

2. Et trægulv er så fugtfølsomt, at det altid kræver en fugtspærre oven på betonen, som ikke er helt gennemtør.

3. Diffusionstæt gulvbelægning, fx vinyl eller linoleum, direkte på tør beton, dvs. beton i fugtligevægt med den højeste RF, som gulvbelægning og lim kan tåle - ofte 85%.

4. Diffusionstæt gulvbelægning på en fugtspærre på oversiden af betonpladen. Fugtspærren er nødvendig, hvis gulvet lægges, før betonen er udtørret.

Fugtspærren skal hindre fugt i underliggende konstruktioner i at trænge op i fugtfølsomme materialer i gulvkonstruktionen. Fugtspærren skal derfor både være tæt mod kapillarsugning og mod vanddampdiffusion, dvs. den skal være tæt og have en høj Z-værdi. Endvidere skal fugtspærren være tilstrækkelig robust til at tåle håndtering på byggepladsen, fx tåle at blive betrådt i forbindelse med udlægning af gulvet. Kravet til Z-værdiens absolutte størrelse afhænger af Z-værdien af de ovenover liggende lag. Fugtspærren skal specificeres af den projekterende. Som tommelfingerregel kan der regnes med, at Z-værdien af fugtspærren skal være 5-10 gange så høj som for de efterfølgende lag. I praksis volder opfyldelse af kravene til Z-værdien sjældent problemer, fordi fugtspærrer af hensyn til robustheden normalt er så tykke, at der med de anvendte materialetyper opnås en høj Z-værdi.

Almindeligt anvendte materialer til fugtspærrer er:

• PE-folie, tykkelse mindst 0,15 mm af hensyn til robustheden. Z-værdien for 0,15 mm PE-folie er ca. 400 GPa s m2/kg.

Erfaringsmæssigt vil tykkere PE-folier være mere robuste i byggeperioden. Der bør benyttes folier, som har dokumentation for diffusionstæthed og holdbarhed, fx. overholdelse af Svenska Plastförbundets Verksnorm 2001.

Plastfolie er tillige et godt glidelag i svømmende gulve, især hvis det anvendes i to lag, eller i kombination med gulvpap eller lignende produkter.

• Asfaltpap, 2 kg/m2, Z-værdi ca. 500 GPa s m2/kg.

• Støbeasfalt, udlægges normalt i en tykkelse på ca. 25 mm, hvorved der opnås en Z-værdi over 1000 GPa s m2/kg.

• Epoxysystem med dokumenteret funktionsduelighed, fx efter den svenske SP-metod 1310 (Statens Provningsanstalt).

• Specialprodukter fra trægulvleverandører, se leverandørernes anvisninger og produktoplysninger.

• Specialspartelmasser, se leverandørernes anvisninger og produktoplysninger.

Det skal sikres, at der ikke sker perforering af fugtspærren, fx på grund af grater i et underliggende betonlag. Beskyttelse af fugtspærren kan ske med et mellemlag mellem beton og fugtspærre.

Mellemlag

• Mellemlag anvendes i svømmende gulve til at sikre, at gulvpladen kan bevæge sig frit i forhold til den bærende konstruktion.

• Mellemlagene kan i nogle tilfælde samtidig tjene andre formål, fx benyttes sand til afretning, og isoleringsmaterialer til at bedre varme- og lydisolering.

• Mellemlaget må vælges ud fra ønsket om at få et rimeligt stift gulv, der ikke skades af de belastninger, som gulvet er beregnet til, og som heller ikke medfører gener, fx rystelser ved gang eller generende hældninger af møbler og inventar, på grund af gulvets nedbøjninger. Af hensyn til lyddæmpning kan der omvendt være ønsker om at gøre mellemlaget så eftergiveligt som muligt.

Ved valg må der i givet fald tages hensyn til begge forhold.

Ofte kombineres mellemlagene. I svømmende gulve skal underlaget for isoleringsmaterialer fx have en planhed svarende til planhedskravet for den færdige gulvbelægning.Dette kan fx opnås ved at oprette med løst granulat, før isoleringsmaterialet udlægges.

Skumplast, korksmuldpap og lignende produkter

• Skumplast, korksmuldpap og lignende produkter udlægges løst under pladegulve for at udligne tryk og som glidelag.

• Produkterne bidrager desuden til at forbedre lydforholdene ved at hindre "klapren" mod det bærende underlag og ved at dæmpe trinlyd og trommelyd.

• Nogle af produkterne fungerer også som fugtspærre, så en yderligere fugtspærre ikke er nødvendig.

• Der bør anvendes produkter, som er anbefalet af gulvproducenten/- leverandøren, så der er sikkerhed for, at produkterne har de ønskede egenskaber, herunder holdbarhed.

Gummikork/korkment

• Gummikork/korkment i baner benyttes som trykfordelende lag og bidrager til at forbedre trinlydsegenskaberne og gulvets eftergivelighed.

• Virkningen afhænger af produktets tykkelse og materialesammensætning. Materialerne kan også benyttes limet til underlaget.

Gulvpap

• Gulvpap benyttes som underlag for pladegulve for at reducere klaprelyde.

• Gulvpap er en uimprægneret pap, normalt med en fladevægt på 500 g/m2.

Isoleringsmaterialer

• Isoleringsmaterialer anvendes i gulvkonstruktioner for at forbedre lyd- og varmeisoleringen.

• Ved strø- eller bjælkekonstruktioner kan der indlægges blød mineraluld mellem strøer og bjælker, hvor det bl.a. kan absorbere lyd.

• I svømmende gulvkonstruktioner benyttes isoleringen til at hindre transmission af trinlyd fra gulvet til den bærende konstruktion, samtidig med at den overfører belastningen. Af hensyn til trinlyd skal isoleringslaget være så eftergiveligt som muligt, mens det af hensyn til trægulvets styrke og stivhed skal være så hårdt som muligt.

• Den nødvendige stivhed af isoleringslaget bestemmes ud fra den forventede belastning, isoleringslagets tykkelse og gulvmaterialet. Der kan groft regnes med, at mineraluld skal have en densitet på 75-130 kg/m3 og polystyren 30-40 kg/m3 afhængigt af lagtykkelse, pladetykkelse og belastning.

• Mellem isoleringsplader og pladegulv udlægges ofte korkparkolag, ribbepap eller lignende for undgå generende lyd.

Sand

• Sand, der benyttes som underlag for svømmende gulve, skal være velgraderet, med kornstørrelse 1-4 mm og ovntørret. Alle fraktioner af kornkurven skal være til stede, så der er sikkerhed for, at sandet pakker ordentligt ved udlægning og komprimering.

• Sand udlægges efter ledere. Hvis lagtykkelsen overstiger 60 mm skal udlægning ske i flere omgange med vibrering for hver påbegyndt 60 mm.

• Sandlag skal dækkes af et egnet afdækningsmateriale inden udlægning af plademateriale, fx 0,2 mm polyethylenfolie, asfaltpap eller korkparkolag.

Gipsgranulat

• Gipsgranulat skal være velgraderet med en kornstørrelse på 1-5 mm. Densiteten skal være 400 - 600 kg/m3.

• Gipsgranulat skal udlægges i mindst 15 mm tykkelse. Ved større lagtykkelser skal der vibreres for hver påbegyndt 50 mm.

• Afrettet gipsgranulat skal dækkes af et egnet afdækningsmateriale inden udlægning af plademateriale, fx ribbepap, gulvpap eller tilsvarende.

Perlite

• Perlite er et vulkansk materiale med en densitet på ca. 150 kg/m3. Perlite skal udlægges i mindst 15 mm tykkelse. Ved større lagtykkelser skal der komprimeres for hver påbegyndt 50 mm.

• Afrettet perlite skal dækkes af et egnet afdækningsmateriale (plademateriale) inden udlægning af gulvplader.

Hørfibre Bitumenimprægnerede

• Hørfibre skal have en densitet på mindst 150 kg/m3. Fibrene udlægges efter ledere med lagtykkelse mellem 5 og 400 mm. Der skal komprimeres for hver 35 mm.

• Afrettede hørfibre skal dækkes af et egnet afdækningsmateriale inden udlægning af plademateriale, fx ribbepap, gulvpap eller tilsvarende.

2.1.1.11 Dilatationsfuger

Dilatationsfuger i den bærende konstruktion skal altid føres igennem gulvkonstruktionen inklusive gulvbelægningen.

I svømmende gulve kan der være behov for yderligere fuger afhængigt af konstruktionsopbygning, gulvets geometri og belastningen.

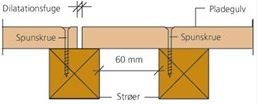

Figur 5. Eksempel på udførelse af dilatationsfuge i pladegulv på strøer.

Yderligere oplysninger om fuger i gulve findes i "Fugemappen" udgivet af Fugebranchens Samarbejds- og Oplysningsråd (FSO).

2.1.1.12 Strøkonstruktioner

Strøer kan udføres i massivt eller lamineret træ.

Strøer i massivt træ skal være skarpkantede lægter med en bredde på mindst 45 mm (høvlet mål).

Strøer i lamineret træ (fx Kerto) skal have en bredde på mindst 40 mm, så der ikke er risiko for flækning.

Strøerne bør leveres så lange som muligt, da det bedste resultat opnås med lægter i fuld længde. Længder på indtil 3,9 m er normal lagervare, og større længder op til 4,8 m kan normalt leveres på bestilling.

Strøer bør mindst være høvlet på den side, som vender op mod pladerne.

Strøerne skal være så rette, at deres overflade efter udlægning højst afviger ± 2 mm på et 2 m retholt.

Efter udlægning bør der højst være afvigelser sideværts på 5 mm fra rethed på 2 m (afvigelse fra retholt der anbringes på den hule side af strøen).

Strøerne må ikke vride mere end, at de ved løs udlægning med den ene ende fastholdt mod gulvet højst "gaber" 2 mm pr. 2 m strølængde ved et hjørne i modsatte strøende. For en strø på fx 3,9 m svarer det til, at vridningen højst medfører et "gab" på ca. 4 mm.

Strøerne skal være af en kvalitet, så krav til knaster svarer til sorteringsreglerne for DK 18. Dette betyder, at enkeltknaster højst må udgøre 1/3 x tværsnitsarealet og knastgrupper højst 1/2 x tværsnitsarealet.

Det bedste resultat opnås, hvis fugtindholdet af strøerne ved lægningen svarer til pladernes. Dette reducerer bl.a. problemer med knirken. Fugtindholdet i strøerne må ved lægning aldrig være over 12 %. Dette betyder, at gennemsnittet af de målinger, der foretages, højst må være 12 %, og at der normalt ikke bør forekomme enkeltresultater højere end 14 %.

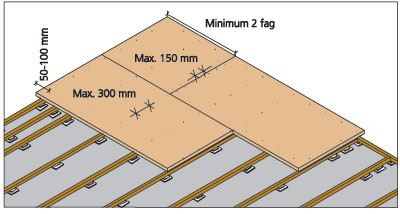

Figur 6. Strøkonstruktion til gulvplader. Alle pladestykker bør spænde over mindst 2 fag. Alle frie pladekanter, fx langs vægge, skal understøttes.

Strø- og bjælkeafstande for bærende pladegulve fremgår af tabellerne i afsnittene om de respektive pladetyper.

De angivne afstande sikrer et rimeligt stift gulv, der ikke giver generende rystelser ved gang, eller medfører at møbler og inventar får generende hældninger på grund af gulvets nedbøjning.

Understøtningsafstanden er afhængig af den valgte materialetykkelse og den forventede belastning.

Se også gulvfaktas afsnit om "Strøer - materiale" og "Strøafstande"