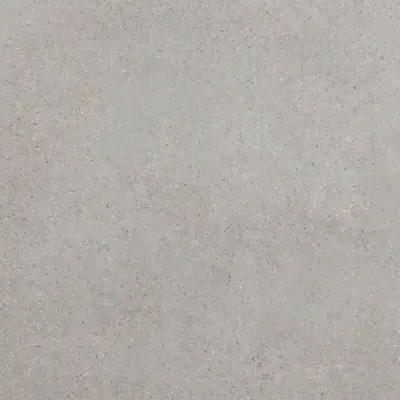

Unicom star Polestar Cloud 60x120 cm. tile

Shelf no.: 18 (30x60 cm.)

Application: Floor/wall tile

Country of manufacture: Italy

Colour: Grey

Size: 600x1200 mm.

Wear resistance: 3

Production method: Rectified

Thickness: 10 mm.

Frostproof: Yes

Color variation: V2

Slip resistance: R11

Surface: Matt

Content per pk.: 1.44 m 2

Below you can see explanations of the descriptions you will find on our tiles.

Shelf number, what does it mean?

When you visit our showroom, you can easily find the tile, as the shelf number is also indicated on the tile in our exhibition.

Floor or wall tile?

Here you can see whether the tile can be used on the wall or floor. A floor tile can be used as a wall tile, but not vice versa.

Production country?

The country in which the tile is produced is indicated here.

Color?

Here we describe the color of the tile as best we can.

Size?

Tiles are available in many sizes, here you can see the size of the tile in mm.

Wear resistance?

Depending on which room you need to change your tiles, the wear resistance will be decisive for your choice. Abrasion resistance is the roughness of the surface and how vulnerable it is to scratches and wear. If it is a room with a lot of traffic, a tile with high wear resistance will be needed. The wear resistance is divided into 5 categories from 1 - 5, with 5 being the strongest. However, there is also a wear resistance U, and all the categories are described below:

Wear resistance 1: Used for wall tiles in all rooms.

Wear resistance 2: For floors with less/limited traffic, including for example bathrooms.

Wear resistance 3: For private homes, for floors where there is less traffic, with light footwear without dirt, for example entrances.

Wear resistance 4: Can be used anywhere in private homes where there is a lot of traffic, including on the terrace.

Wear resistance 5: The tile can be used anywhere where there is a lot of traffic, and in both public and private homes.

Abrasion resistance U: U stands for unglazed, or impervious. This tile is used for heavy wear, such as restaurants, shopping centers, banks, schools, etc.

Production method?

Rectification, what does it mean?

If the tile is rectified, it is finely cut on all edges after it has been finished. This means that the joints can be narrow, down to 1.8 mm. When cutting tiles, there must be a deviation of 0.2%.

Molded, what does that mean?

Molded tiles must vary by 5 mm, and require a larger joint. This means that we recommend the joint must be at least 6 mm (legal requirement 5 mm). A molded tile "contracts" during firing, which is why the dimensions of the tile can vary.

Thickness?

Here you see the thickness of the tile in millimeters.

Frostproof?

Here you can see whether the tile can withstand frost, i.e. whether it can also be used outside.

Color variation?

Indicates how much variation there is in the tile, seen over a larger area. It can therefore be difficult to choose a V4 tile based on a 30x60 sample. V1-V2-V3-V4 are the designations used, and the higher the number, the more variation there is in the tile.

Anti-slip?

The slip resistance of a tile is measured/classified from R9 – R13. The higher the value, the more non-slip and rough the tile is. Always measure on a dry tile.

R9 – R11: Is normally for indoor use in private homes.

R12 – R13: Is for industrial use, and for outdoor areas and stairs. Typically for butcher shops, industrial and restaurant kitchens, etc

The higher the slip resistance, the more challenging the cleaning, and R12 typically requires high-pressure flushing when cleaning. For private homes, sufficient slip resistance is usually achieved, partly by ensuring that the tiles are clean and free of soap residue etc