Marmoleum Striato Original - Withered Prairie

The natural and renewable raw materials make Marmoleum linoleum flooring the most durable elastic floor in the market. It is PVC-free and contains no plasticizers or mineral oils.

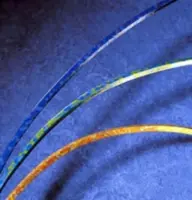

Marmoleum Striato Original

In Marmoleum Striato original, the palette is neutral with warm tones and trendy gray shades from light to dark, which looks really nice in itself, but also in combination with other flooring.

The discrete linear pattern will easily match other colors in the surroundings and harmonize easily with other materials.

Thickness: 2.5 mm

Roller width: 200 cm

Roll length: Up to 32 meters.

NCS: S 5010-Y30R

LRV: 23%

Durable & durable floor

97% natural ingredients

72% fast renewed materials

43% recycled materials

Highest performance created by nature

The natural and renewable raw materials make Marmoleum the most durable elastic floor in the market. It is PVC-free and contains no plasticizers or mineral oils.

The most important ingredients in Marmoleum are:

- Linseed oil that comes from the flax seed

- Wood flour from controlled forests

- Jute, the natural carrier tissue that forms the back of linoleum

Marmoleum has the important global environmental certificates such as the Swan and Blue Angel.

Topshield is Forbo's high-performance UV finish, which forms the surface of all Marmoleum course products and tiles. Topshield which makes the coating resistant to stains, scratches and dirt and creates a long lasting beautiful floor. It also makes the floor easier to clean and maintain year after year.

Cleaning of Marmoleum floors

Forbo's floor coverings meet the great demands placed on floors in both private homes and public environments. The floors must be able to function for many years under heavy impact while maintaining the beautiful appearance and high performance.

There is a clear correlation between how floors look and the way you clean and maintain them. The procedure, frequency of cleaning and means depend on the impacts the floor is exposed to.

You will find the cleaning instructions here

Easy to mount

In order to achieve a perfect result, it is important that the floor covering is installed correctly. See our installation instructions.

The key factors for a successful mounting of a durable floor are the following:

Preparing the subfloor

Mounting a durable Forbo floor begins with the subfloor, which must be dry, stable and level. Forbo QuickFit is a wood fiber based, fast mounted alternative to the traditional subfloor system. Forbo QuickFit is especially suitable in smaller areas where it must be mounted without the use of nails, and glue and in places where it may be. is needed for extra step sound attenuation.

Installation Plan

It is important to prepare a good plan before the installation starts. Rooms, materials and subfloors must have a temperature of at least 17 degrees. The materials must have time to acclimate the minimum overnight before assembly. Forbo offers specially designed mounting tools for transport and roll-out, eg. Forbocar or Forbo Carryset.

Scratching and cutting

A good start is crucial: Pay special attention to the first course! A perfect result is achieved through professional mounting tools.

Bonding

A perfectly fitted floor requires perfect adhesion. Remember to drum the floor after mounting to obtain a correct adhesive joint. Always follow the adhesive manufacturer's instructions.

After installation, it is important that the room is ventilated so that the glue can dry. A newly installed floor must not be used or applied to weight before the glue has dried completely, which typically takes 2 days under normal conditions.

welding

Welding is done as a decoration and / or for cleaning reasons. When the glue is sufficiently hardened, which usually lasts a day, the fuse wire can be mounted. Follow the instructions in our installation instructions and on the side of the welding wire roller thoroughly.

finish

To achieve a professional finish, the floor must have a finish and there are of course many quality products for this purpose. Foot panels, staircases and transition profiles in different materials can be used to create a perfect result.

Forbo also supplies hollow-core systems for finishing against walls.

You will find the installation instructions here .