- Forside

- Gode råd om gulv

- Gulvbelægninger

- Valg af gulv

- Akustikpaneler

- Afpassede tæpper

- Bambusgulve

- Bordplader & bordben

- Designgulve

- Fliser og klinker

- BeefEater gasgrill

- Gode råd om gulv

- Gulvtæpper

- Gulvvarme

- Græstæpper

- Korkgulve

- Køkken, bad & garderobe

- Laminatgulve

- Linoleumsgulve

- Maling, Væv & Spartel

- Måtter

- Møbler & Boliginteriør

- Nålefilt og messetæpper

- Plejeprodukter

- Restpartier & gode tilbud

- Sildebensparket & Stavparket

- Tæppefliser

- Terrassebrædder

- Tilbehør

- Trægulve

- Vareprøver

- Vinylgulv

- Værktøj

- Øvrige produkter

- Loft- og vægpaneler

- Flotte gulve

- Fyrretræsgulv

- Klikgulve

- Bestilte varer

-

-26%

-

Populær29,00 DKK

-

29,00 DKK pr m2

-

Populær21,00 DKK

-

-59%39,00 DKK pr m295,00 DKKDu sparer: 56,00 DKK pr m2

Valg af gulv

Alle informationer på denne side er kopieret materiale fra Gulvfakta som er et fagteknisk opslagsmateriale, Kilde: Gulvfakta

Ved valg af gulv må der tages hensyn til en række forskellige forhold, blandt andet brugsegenskaber, økonomi, æstetik, udførelsesmetoder og miljømæssige forhold. Disse egenskaber er beskrevet i dette kapitlet.

1.1.0.1 Gulvopbygning - terminologi

1.1.0.2 Hvad skal indgå ved valg af gulv?

1.1.0.3 Pris - totaløkonomi

1.1.0.4 Brug af checklister ved valg

1.1.0.5 Eksempler på checklister

1.1.0.6 Værdianalyse

Alle informationer på denne side er kopieret materiale fra Gulvfakta som er et fagteknisk opslagsmateriale. Kilde: Gulvfakta

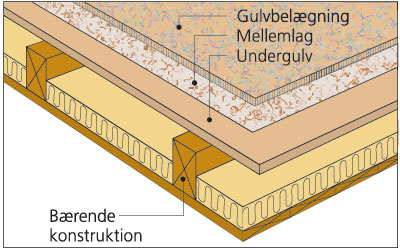

1.1.0.1 Gulvopbygning - terminologi

Gulvbelægninger, som udgør den færdige gulvflade, er det øverste selvstændige lag i gulvet. Det kan fx være tæppe, linoleum, gummi, vinyl, kork, laminat eller parketstave. Lak eller anden overfladebehandling betragtes ikke som en selvstændig belægning.

Undergulve ligger under gulvbelægningen, men over den bærende konstruktion. Undergulvet skal danne en sammenhængende flade, så det fx kan benyttes som arbejdsgulv og underlag for en tynd belægning. Det kan fx være et svømmende gulv, et pladegulv på strøer eller et afretningslag af beton.

Bemærk, at tynde isoleringslag, korksmuldpap o.lign. benævnes mellemlag og ikke betragtes som undergulv.

Den bærende konstruktion består af lag, hvis primære funktion er at optage og overføre last, eksempelvis betondæk og træbjælkelag.

Fig. 1. Gulvopbygning - terminologi

Fig. 1. Gulvopbygning - terminologi

Gulvopbygning- definitioner

Gulve kan opdeles i to hovedtyper efter deres konstruktive opbygning, nemlig:

Bærende gulve, som omfatter:

• Strøgulve (trægulve lagt på strøer)

• Trægulve på træbjælkelag

Ikke-bærende gulve, som omfatter:

• Svømmende gulve

• Limede gulve

• Sømmede gulve

• Fugefrie gulve

• Løst udlagte gulvbelægninger

Bærende gule

Ved bærende gulve forstås gulve, som hviler på en lineær understøtning af strøer eller bjælker. Belastningen på gulvet overføres gennem brædder eller plader til de underliggende strøer eller bjælker, se figur 2.

Fig. 2. Bærende gulv (strøgulv)

Fig. 2. Bærende gulv (strøgulv)

Ikke-bærende gulve

Ved ikke-bærende gulve forstås gulve, hvor gulvbelægningen er understøttet i fuld gulvflade af et bærende underlag, fx et undergulv af beton eller træplader, se figur 3.

Fig. 3. Ikke bærende gulv

Fig. 3. Ikke bærende gulv

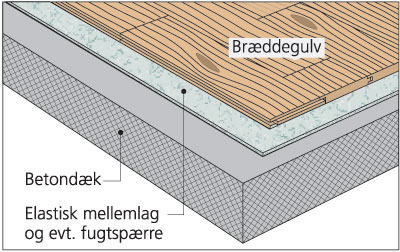

Svømmende gulve

Et svømmende gulv er et gulv, hvor gulvfladen kan bevæge sig frit i forhold til det bærende underlag. Dette opnås ved, at der mellem gulvfladen og det bærende underlag indlægges et elastisk mellemlag, så der er sikkerhed for, at gulvfladen kan bevæge sig frit. Med et svømmende gulv er gulvfladen således hverken sømmet eller limet fast til underlaget. Mellemlaget kan udføres af materialer, der bidrager til at forbedre varmeisoleringen og de lydmæssige egenskaber. Når du vælger et svømmende gulv, er det vigtigt at underlaget er plant, da belastningen på selve gulvet ellers vil være ulige fordelt, som kan få gulvet til at bøje eller sprække.

Fig. 4. Svømmende gulv

Fig. 4. Svømmende gulv

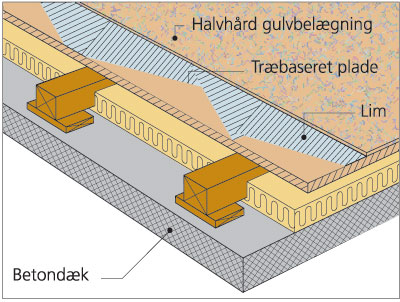

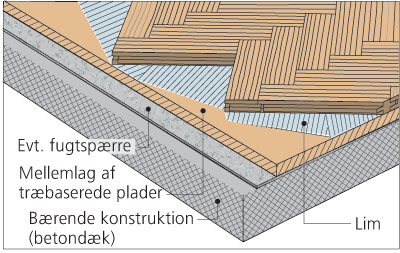

Limede gulve

Limede gulve lægges i fast forbindelse med et bærende, plant og stabilt underlag og understøttes i fuld flade. Underlaget kan fx bestå af et beton- eller letbetondæk eller et svømmende undergulv, fx af sammenlimede træplader.

Fig. 5. Limet/sømmet gulv

Fig. 5. Limet/sømmet gulv

Sømmede gulve

Sømmede gulve lægges i fast forbindelse med et bærende, plant og stabilt underlag og understøttes i fuld flade. Underlaget kan fx bestå af et beton- eller letbetondæk eller et svømmende undergulv, fx af sammenlimede træplader.

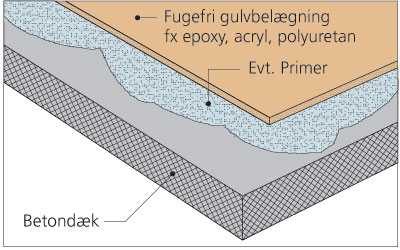

Fugefrie gulve

Fugefrie gulve lægges på et bærende, plant og stabilt underlag og understøttes i fuld flade. Normalt er underlaget af beton.

Løst udlagte gulvbelægninger

Løst udlagte gulvbelægninger lægges på et bærende, plant og stabilt underlag og understøttes i fuld flade. Underlaget kan fx bestå af et beton- eller letbetondæk eller et eksisterende trægulv.

1.1.0.2 Hvad skal indgå ved valg af gulv?

Ved valg af gulv må der tages hensyn til en række forskellige forhold:

• Teknik (nødvendige brugsegenskaber)

• Pris (totaløkonomi dvs. såvel anlægsudgifter som fremtidige driftsudgifter, fx udgifter til vedligehold og rengøring)

• Æstetik (udseende)

• Udførelsesmetode (gener, tidsforbrug)

• Miljømæssige forhold (påvirkning af indeklima og omgivelser, brug af ressourcer

Se også kapitlet om teknik og kvalitet.

Af praktiske og økonomiske grunde vil det som regel være nødvendigt at begrænse de egenskaber, der stilles krav til. De egenskaber, der udvælges, skal derfor være de vigtigste - nøgleegenskaberne - for gulvet. Til hjælp ved udvælgelsen blandt de mange egenskaber er der udarbejdet checklister for de forskellige typer gulvbelægning. Ved valg eller projektering kan checklisterne gennemgås med bygherren. Derved sikres det, at alle væsentlige forhold er blevet overvejet. Bemærk, at det er de nødvendige krav til egenskaber, der skal fastlægges. Stilles der højere krav end nødvendigt, vil det næsten uundgåeligt samtidig føre til højere pris.

1.1.0.3 Pris - totaløkonomi

Som regel har prisen stor indflydelse ved valg af gulv. For at sikre bygherren det bedste udbytte, bør totaløkonomi prioriteres højere end lav anskaffelsespris, fx bør konstruktioner og materialer med lang levetid og lave vedligeholdsudgifter vægtes højere end lav anskaffelsespris.

For at vurdere totaløkonomien kræves der oplysninger om:

Gulvets Levetid

Som regel er det især gulvbelægningens levetid, det drejer sig om. Der bør gives så godt et skøn som muligt, fx baseret på oplysninger fra levetidstabeller eller leverandøroplysninger kombineret med viden om indflydelsen af den påtænkte brug, herunder brugsintensitet og -belastning. Heri kan også indgå skøn over udskiftningsintervaller. Levetidstabeller kan fx fås fra Forsikring og Pension eller Byggeriets Udviklingsråd.

Gulvets vedligeholdsudgifter

Herunder udgifter til overfladebehandling, rengøring og eventuelle forventede småreparationer. Udgifter til rengøring kan skaffes ved at inddrage rengøringsfaglig ekspertise, fx uafhængige rådgivere eller rengøringsfirmaer. Bemærk, Valg af gulv September 2005 Hvad skal indgå ved valg af gulv?

Hvis der rengøres efter en metode, som afviger fra den foreskrevne, kan det medføre skader på gulvbelægningen, herunder nedsat levetid.

Den forventede prisudvikling

Der må foretages et skøn over den prisudvikling, der forventes for vedligeholdsarbejdet i forhold til den almindelige prisudvikling i hele gulvets levetid.

Realrenten

Der må foretages et skøn over rentefoden renset for inflation.

På Gulvbranchen hjemmeside kan du finde en model til beregning af totaløkonomien for forskellige typer af gulve. Beregningsmodellen følger principperne fra bl.a. GBC om end den på nogle områder er simplificeret og på andre områder er langt mede detaljeret. Modellen opererer med en tidshorisont på 50 år og medtager udgifter til installation, rengøring og vedligeholelse samt udskiftning og bortskaffelse/fornyelse. Rengørings processer og priser er indhentet hos et eksternt konsulentfirma. Beregningsmodellen anvender data omkring de forskellige belægningers levetid , defineret ved den tid der erfaringsmæssigt går fra en belægnig installeres til den udskiftes (udskiftningen sker IKKE nødvendigvis pga svigt i belægningen, udskiftningen sker oftere pga ændrede krav/ønsker til overflader, farver og mønstre olign). Modellen og tilhørende vejledning kan downloades her.

Gulvets æstetik

Æstetik kan ikke behandles objektivt men skal altid overvejes ved valg af gulv. I vurderingen kan fx indgå arkitektonisk udtryk, farve, tekstur, lysrefleksion og mønster.

Udførelsesmetode

I mange tilfælde må der i forbindelse med valg af gulvkonstruktion tages hensyn til hvilken udførelsesmetode, der kan/skal anvendes. Dette skyldes, at udførelsesmetoden er afgørende for, hvor lang tid gulvlægningsarbejdet tager, og hvor mange gener det medfører. Blandt andet må det overvejes, om det er acceptabelt, at opbygningen af gulvkonstruktionen tilfører byggefugt, kræver særligt sikkerhedsudstyr eller kræver lange hærdetider.

Miljøpåvirkninger

Materialerne, der benyttes til gulvet, må ikke medføre indeklimamæssige gener, fx i form af afgasning af generende eller sundhedsskadelige stoffer. Materialerne må heller ikke ved produktion, brug eller bortskaffelse give anledning til forøget risiko for skade på omgivelserne, fx forurening. Endelig må materialerne ikke medføre unødigt forbrug af ikke-fornyelige ressourcer. Ved vurdering af problemer af denne art benyttes som regel LCA-begrebet, dvs. vurdering af produktet i hele livscyklusforløbet. Der henvises til speciallitteraturen, som fx kan findes gennem Miljøstyrelsen. Mange egenskaber for et gulv afhænger af gulvbelægningen og de øvrige egenskaber bestemmes især ved en samvirken mellem gulvbelægningen og det anvendte underlag. Det vil derfor ofte være naturligt at vælge gulvbelægningen først og dernæst projektere underlaget, så øvrige krav til den samlede konstruktion er opfyldt.

Det er ikke muligt at sammenligne tekniske egenskaber for gulvbelægninger "på tværs" af materialetyper. Valg mellem typerne må derfor ske på grundlag af det, den projekterende og/eller bygherren anser for at være fordele og ulemper ved de forskellige materialetyper. Elastiske gulvbelægninger, textilgulvbelægninger og laminatgulve klassificeres efter et europæisk klassifikationssystem, som fastlægger forskellige brugsområder. Klassifikationen er beskrevet i EN standarder, som er specifikke for hver gulvbelægningstype. Materialer, som er deklareret til brug i en af disse klasser, opfylder visse nærmere specificerede egenskaber, som afhænger af belægningstypen. Se fx checkliste 1, som er gældende for linoleum.

Det vil ofte være hensigtsmæssigt at benytte en checkliste i forbindelse med valg af gulvbelægning. Derved sikres en systematisk gennemgang af alle væsentlige forhold og egenskaber ved det aktuelle gulv. Der er udarbejdet separate forslag til checklister for de elastiske gulvbelægninger, som behandles i Gulvfakta. Forslagene findes i afsnittene om de enkelte typer gulvbelægning. Generelt gælder, at checklisterne er delt i to dele.

Den første del indeholder de egenskaber, som er omfattet af EN-klassifikationen for den pågældende type gulvbelægning. EN-klassifikationen er lavet med klasser svarende til anvendelse i henholdsvis bolig, erhverv og industri. Vælges der en gulvbelægning fra en klasse, som svarer til den aktuelle anvendelse, ved man derfor i forvejen, at gulvbelægningen besidder de vigtigste brugsegenskaber for denne anvendelse. Egenskaberne fremgår af checklisten, og værdierne for klassificerede produkter er markeret med "farve". Det er derfor kun nødvendigt at stille krav til disse egenskaber, hvis der ønskes en højere egenskabsværdi end angivet.

Den anden del af checklisterne indeholder egenskaber, som ikke er omfattet af EN -klassifikationen. Egenskaberne i denne del af checklisten benyttes især, hvis der er særlige forhold at tage hensyn til, fx krav til egnethed som afledende gulvbelægning eller egnethed til brug i forbindelse med gulvvarme. For egenskaberne i denne del er man henvist til selv at fastsætte de egenskabsværdier, som er nødvendige. Der er for hver egenskab givet forslag til kravniveauer, som kan benyttes afhængigt af den forventede brug.

Valg af egenskabsværdier

Egenskabsværdierne for de enkelte egenskaber vælges uafhængigt af hinanden. Til et aktuel brug kan der fx være behov for at stille høje krav til nogle bestemte egenskaber, hvilket betyder, at man skal vælge værdier i højre side af skemaet. For andre kan der derimod være lave eller slet ingen krav, og for disse egenskaber kan der vælges egenskaber fra skemaets venstre side. Der stilles altså kun store krav til egenskaberne, når der virkelig er behov for det. Et eksempel på hvordan der skiftevis vælges egenskabsværdier "til højre", "til venstre" og "i midten" er vist her på siden. De valgte egenskabsværdier kan eventuelt forbindes, så der fremkommer en såkaldt kravprofil, dvs. en profil som egenskab for egenskab viser, hvad der kræves af gulvbelægningen. Den ideelle gulvbelægning til et givet formål skal have egenskaber, som optegnet som et profil, er magen til kravprofilen.

For linoleum kan en kravprofil fx se ud, som vist i det følgende eksempel, hvor egenskaberne er valgt på baggrund af checklisterne, der findes i gennemgangen af de enkelte belægningstyper, fx elastiske gulvbelægninger.

1.1.0.4 Brug af checklister ved valg

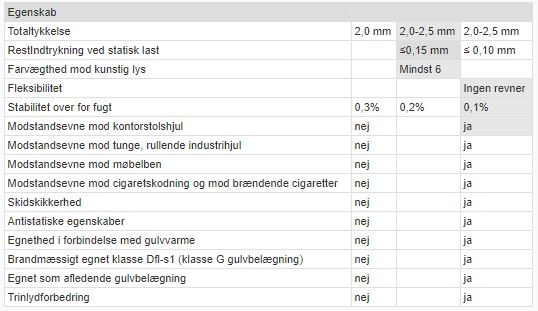

Eksempel på kravprofil for linoleumsgulv

Til en erhvervsbygning skal der benyttes linoleumsgulv som gulvbelægning på gangarealerne.

Der vælges en 2,5 mm. tyk belægning, som er EN-klassificeret. Herved sikres de markerede værdier for tykkelse, restindtrykning ved statisk last, farveægthed, fleksibilitet og stabilitet overfor fugt.

Der forventes påvirkning af kontorstolshjul, tunge, rullende industrihjul og møbelben, hvorfor det markeres at belægningen skal kunne tåle disse påvirkninger.

Desuden ønskes en belægning, som ikke påvirkes af cigaretgløder.

Da der ikke er specielle krav til skridsikkerhed, vælges den laveste værdi.

Der ønskes en gulvbelægning, som ikke oplader statisk elektricitet ved brug.

Der skal ikke anvendes gulvvarme.

Da gulvbelægningen skal bruges i flugtvejsområder, vælges ja ud for brandmæssigt egnet klasse Dfl-s.1 (klasse G gulvbelægning).

Belægningen skal ikke benyttes som en afledende gulvbelægning.

Der ønskes de bedst mulige lydforhold, hvorfor det markeres, at gulvbelægningen skal kunne bidrage til en trinlydforbedring.

1.1.0.5 Eksempler på checklister

De viste checklister (1 og 2) gælder for linoleum. For hver egenskab skal der vælges til højre i skemaet, hvis der er store ønsker/krav, i midten for middel ønsker/krav og til venstre for små eller ingen krav. Af økonomiske årsager bør der ikke stilles større krav end nødvendigt af tekniske, æstetiske eller andre grunde.

Checkliste 1 viser de egenskaber, som indgår i EN-klassifikationen af linoleumsgulve. Klassifikation af linoleum til brug i henholdsvis boliger, erhverv og industri sker på grundlag af tykkelsen. Klasserne kan yderligere underdeles i moderat, normal, høj (og meget høj). Øvrige egenskaber overholder for EN-klassificerede produkter de markerede værdier. De angivne værdier er minimumsværdier.

Checkliste 2. Supplerende egenskaber, som der kan være behov for at stille krav til, fx på grund af særlige påvirkninger af gulvet ved den aktuelle brug.

1.1.0.6 Værdianalyse

Ved valg stilles man overfor spørgsmål som:

• Hvad er vigtigst: pris, udseende eller brugsmæssige egenskaber?

• Hvor meget skal man i givet fald betale mere for, at en egenskab har en højere værdi?

• Hvad gør man, hvis det ikke er muligt at finde et produkt med den rigtige egenskabsprofil?

• Hvordan kan der tages hensyn til miljø, og hvad kan/ vil man betale for det?

Spørgsmål af denne type kan ikke besvares generelt, men kræver en mere dybtgående analyse. Der findes til dette brug et værktøj i form af værdianalyse. Kort fortalt gives de forskellige faktorer: teknik, pris, arbejdsudførelse, æstetik og miljø, hver sin vægt, afhængigt af hvor vigtige de er for bygherren. Herved bliver det fx muligt at finde værdien af en højere teknisk kvalitet, eller et billigt tilbud, som til gengæld ikke lever op til alle de stillede krav. Der henvises i øvrigt til "Værdianalyse ved udbud i totalentreprise", B. Kold Larsen og M. Høgsted, Teknisk Forlag 1976.

Hvordan vælges gulv?

Brugbare løsninger kan findes ved:

• At sammenholde ønsker og krav til nødvendige egenskaber for gulvbelægningen med egenskaberne for de løsninger, der tilbydes.

• At vælge en af de brugbare gulvbelægninger og projektere underlaget, så resterende krav til den samlede gulvkonstruktion opfyldes.

Vigtige egenskaber for gulvunderlag

For at den samlede gulvkonstruktion skal fungere som ønsket, skal der være en samvirken mellem gulvbelægningen og dens underlag/undergulv og desuden med omgivelserne, fx den bærende konstruktion, underliggende terræn eller omgivende vægge. Det er derfor nødvendigt, at underlaget har en række egenskaber, som dels afhænger af den aktuelle gulvbelægning, dels af bygningsfysiske krav til hele gulvkonstruktionen. De nødvendige egenskaber er derfor ikke de samme for alle gulvunderlag. I det følgende omtales kortfattet nogle af de egenskaber for gulvunderlag, som især kan være vigtige:

Bæreevne

Gulvunderlaget skal være i stand til at overføre de belastninger, der kan forventes ved den forudsete brug, uden at der opstår skader eller deformationer.

Styrke og stivhed/elasticitet

Underlaget for gulvbelægningen skal kunne modstå de statiske og dynamiske belastninger, fx fra nyttelast, møbler, personer og rullende færdsel, som normalt må forventes at forekomme ved den påtænkte brug.

Af hensyn til gangbehagelighed kan en vis eftergivelighed (elasticitet) være ønskelig, mens der på den anden side ikke må ske for store deformationer på grund af almindelig last under brug.

Planhed

Underlaget for gulvbelægningen skal være så plant, at gulvet kan opnå den ønskede planhed. For tynde gulvbelægninger og ikke-bærende trægulve betyder dette, at underlaget skal kunne udlægges med samme planhed, som der ønskes af det færdige gulv.

Fugtspærrende virkning

Af hensyn til at mindske risikoen for skader på grund af fugttransport nedefra, fx på grund af byggefugt, kan det være nødvendigt at forsyne gulvunderlaget med en fugtspærre.

Lydtekniske egenskaber

Underlaget skal have sådanne lydtekniske egenskaber, at det kan medvirke til at reducere transmission af luftlyd og trinlyd

Varmebestandighed

Gulvmaterialer, der skal benyttes i forbindelse med gulvvarmeanlæg, skal kunne tåle de temperaturer, der kan forventes at optræde i den aktuelle konstruktion.

Varmeisolerende virkning

Gulvunderlaget skal medvirke til varmeisoleringen af dækkonstruktionen.

Stabilitet overfor fugt

Gulvet må ikke få skadelige deformationer, der skyldes fugtpåvirkninger fra normalt brug.

Højdeudjævnende

Gulvunderlaget skal være i stand til at optage mindre højdeforskelle i den underliggende bærende konstruktion.

Levetid

Gulvunderlaget skal bibeholde sine egenskaber i tilfredsstillende omfang i en længere årrække udsat for normale nedbrydningsfaktorer, fx fugt eller fysiske spændinger fra brugen.