- Forside

- Gode råd om gulv

- Gulvbelægninger

- Elastiske gulvbelægninger

- Kork og vinylkork

- Akustikpaneler

- Afpassede tæpper

- Bambusgulve

- Bordplader & bordben

- Designgulve

- Fliser og klinker

- BeefEater gasgrill

- Gode råd om gulv

- Gulvtæpper

- Gulvvarme

- Græstæpper

- Korkgulve

- Køkken, bad & garderobe

- Laminatgulve

- Linoleumsgulve

- Maling, Væv & Spartel

- Måtter

- Møbler & Boliginteriør

- Nålefilt og messetæpper

- Plejeprodukter

- Restpartier & gode tilbud

- Sildebensparket & Stavparket

- Tæppefliser

- Terrassebrædder

- Tilbehør

- Trægulve

- Vareprøver

- Vinylgulv

- Værktøj

- Øvrige produkter

- Loft- og vægpaneler

- Flotte gulve

- Fyrretræsgulv

- Klikgulve

- Bestilte varer

-

-26%

-

Populær29,00 DKK

-

29,00 DKK pr m2

-

Populær21,00 DKK

-

-59%39,00 DKK pr m295,00 DKKDu sparer: 56,00 DKK pr m2

Kork og vinylkork

Alle informationer på denne side er kopieret materiale fra Gulvfakta som er et fagteknisk opslagsmateriale, Kilde: Gulvfakta

Kork er et naturprodukt, som fremstilles af barken fra korkegen. Korkgulve leveres enten som naturkork til lakering eller med en rengøringsvenlig og slidstærk overflade i form af en klar vinyl.

1.3.3.1 Introduktion

1.3.3.2 Egenskaber

1.3.3.3 Krav til udførelsesstedet

1.3.3.4 Lægning og brug

1.3.3.5 Rengøring

1.3.3.6 Checkliste 9, 10, 11 og 12

Alle informationer på denne side er kopieret materiale fra Gulvfakta som er et fagteknisk opslagsmateriale, Kilde: Gulvfakta

1.3.3.1 Introduktion

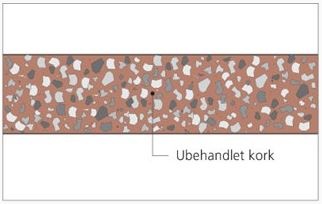

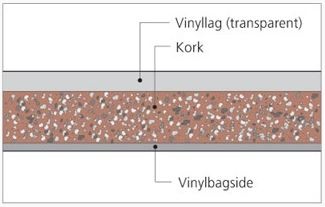

Kork anvendes i tørre rum i skoler, sygehuse, kontorer, butikker, boliger etc. Korkgulvbelægninger leveres som fliser eller som korkplader, dvs. laminerede produkter, hvor korken er fastlimet til en underlagsplade af MDF (træfiberplade). Korkfliser leveres enten ubehandlede i tykkelser op til 8 mm, eller med et slidlag (og underside) af vinyl i tykkelsen 3,2 mm. Vinylslidlagets tykkelse er 0,5 mm. Flisestørrelsen er 300 x 300 mm. Ubehandlede korkfliser skal efter lægningen slibes og lakeres i henhold til leverandørens anvisninger.

Korkfliser med vinyloverflade har overfladeegenskaber svarende til vinyl, dvs. slidstærkt, rengøringsvenlig og med god modstandsevne mod vand og de fleste sure og alkaliske materialer. Langvarig påvirkning af vand bør dog undgås, idet fugt kan trænge ned gennem fugerne.

Korkplader er forsynet med fer og not på alle fire sider og leveres i størrelser 900 x 185 mm og i tykkelser op til 12 mm. Korkplader udlægges løst oven på underlaget, dvs. som svømmende gulv og samles med corkloc system (et kliksystem) uden brug af lim. Kork, der anvendes som gulvbelægning, skal være CE-mærket. Kork der benyttes som gulvbelægning i flugtveje og andre områder med krav til brand og røgudvikling, skal have dokumentation for at opfylde den europæiske brandklasse Dfl-s1 i henhold til DS/EN 13501-1 (klasse G gulvbelægning). Korkgulvbelægninger er behagelige at opholde sig på, idet de er fjedrende og har god varmebehagelighed.

1.3.3.2 Egenskaber

Der findes europæiske standarder for henholdsvis kork med vinyl og kork uden vinyl.

Produkter som opfylder en af de euopæiske standarder på området skal overholde specifikke krav til:

• Længde, bredde og rethed

• Dimensionsstabilitet ved temperaturændringer

• Tykkelse og fladevægt

For kork med klar vinyl skal desuden opgives:

• Tykkelse af belægningens underside

• Densiteten af slidlaget

• Peel aftræksstyrken af overfladen

For ubehandlede korkfliser skal fugtindholdet opgives.

Klassifikation af kork sker efter anvendelsesområde med tykkelsen og densiteten som primære parametre for klassifikationen, for ubehandlede korkfliser. For korkfliser med klar vinyl sker klassifikationen med tykkelsen og tykkelsen af vinylslidlaget som primære parametre. Produkter af begge typer klassificeret til brug i "Erhverv Normal" kan benyttes til kontorstole på hjul og overholder desuden krav til indtrykningsmærker.

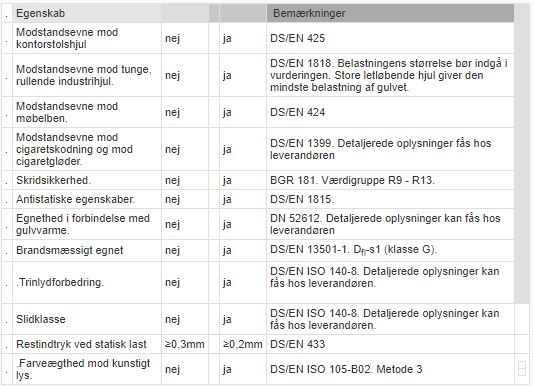

Udover de egenskaber, som indgår i klassifikationen, kan der være behov for at stille krav til andre egenskaber, afhængigt af den aktuelle anvendelse. Disse egenskaber indgår i Gulvbranchens supplerende egenskaber, som for korkgulve omfatter:

1.3.3.3 Krav til udførelsesstedet

Der skal være afsat tid til, at korken kan akklimatiseres. Dette sker ved at anbringe den i uåbnet emballage på lægningsstedet, indtil der er opnået temperaturmæssig ligevægt, hvilket mindst må påregnes at tage 24 timer, afhængigt af temperatur og fugtforhold.

Under og efter limning af kork skal temperaturen i luften og undergulvet være 17 - 25°C og luftfugtigheden mellem 35 og 75% RF. Underlaget skal have samme planhed, som kræves af det færdige gulv, normalt ± 2 mm på et 2 m retholt. Planhed og gulve, herunder krav og målemetoder, er beskrevet i sektionen Teknik og kvalitet. Skal kork udlægges direkte på støbte dæk, må betones porefugt (restbyggefugt) højst være 85% RF. Fugt og gulve, herunder krav og målemetoder, er ligeledes beskrevet i sektionen om Teknik og kvalitet. Der må ikke være kraftig træk eller kraftigt solindfald under lægningen af gulvet. Korkfliser skal lægges på et sugende underlag for at sikre, at limen hæfter godt til underlaget. Såfremt der ikke er tilstrækkelig sugeevne, fx på underlag af asfalt eller epoxy, skal der påføres et mindst 2 mm tykt lag egnet spartelmasse.

1.3.3.4 Lægning og brug

Forhold i forbindelse med lægning og brug

Ved tilskæring af korkfliser til fodpaneler anbefales det, at der laves en fuge på ca. 1 mm. Herved undgås det, at fliserne ved tromling kommer i spænd mod panelerne, hvilket kan resultere i svigt i flisernes vedhæftning til underlaget.

1.3.3.5 Rengøring

De fremtidige brugere skal oplyses om korrekt rengøring, da forkert rengøring kan medføre skader på overfladen. Leverandørens anvisning om rengøring og vedligeholdelse af korkgulve skal udleveres til brugeren. Til daglig rengøring anvendes fortrinsvis tørre metoder, dvs. tør eller fugtmopning eller støvsugning. Til kraftigere, lejlighedsvis rengøring anvendes milde rengøringsmidler uden stærkt alkaliske stoffer. Rengøring af korkgulve er omtalt i sektionen rengøring.

1.3.3.6 Checkliste 9, 10, 11 og 12

Kork uden overfladebehandling

Checkliste 9. Egenskaber, som indgår i EN-klassifikation for korkfliser uden overfladebehandling efter DS/EN 12104. Klassifikation af kork til brug i henholdsvis boliger, erhverv og industri sker på grundlag af tykkelsen og densiteten. Klasserne kan yderligere underdeles i moderat, normal, høj (og meget høj). Øvrige egenskaber overholder for EN-klassificerede produkter de markerede værdier. De angivne værdier er minimumsværdier.

Checkliste 10. Supplerende egenskaber, som der kan være behov for at stille krav til, fx på grund af særlige påvirkninger af gulvet ved den aktuelle brug.

Korkfliser med klar vinyl slidlag

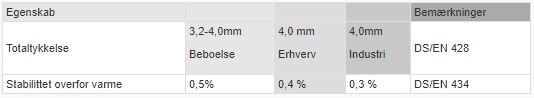

Checkliste 11. Egenskaber, som indgår i EN-Klassifikationen for korkfliser med klart vinyl slidlag efter DS/EN 655. Klassifikation af korkfliser til brug i henholdsvis boliger, erhverv og industri sker på grundlag af tykkelsen og tykkelsen af slidlaget. Klasserne kan yderligere underdeles i moderat, normal, høj (og meget høj). Øvrige egenskaber overholder for EN-klassificerede produkter de markerede værdier. De angivne værdier er minimumsværdier.

Checkliste 12. Supplerende egenskaber, som der kan være behov for at stille krav til, fx på grund af særlige påvirkninger af gulvet ved den aktuelle brug.