- Akustikpaneler

- Afpassede tæpper

- Bambusgulve

- Bordplader & bordben

- Designgulve

- Fliser og klinker

- BeefEater gasgrill

- Gode råd om gulv

- Gulvtæpper

- Gulvvarme

- Græstæpper

- Korkgulve

- Køkken, bad & garderobe

- Laminatgulve

- Linoleumsgulve

- Maling, Væv & Spartel

- Måtter

- Møbler & Boliginteriør

- Nålefilt og messetæpper

- Plejeprodukter

- Restpartier & gode tilbud

- Sildebensparket & Stavparket

- Tæppefliser

- Terrassebrædder

- Tilbehør

- Trægulve

- Vareprøver

- Vinylgulv

- Værktøj

- Øvrige produkter

- Loft- og vægpaneler

- Flotte gulve

- Fyrretræsgulv

- Klikgulve

- Bestilte varer

-

-26%

-

Populær29,00 DKK

-

29,00 DKK pr m2

-

Populær21,00 DKK

-

-59%39,00 DKK pr m295,00 DKKDu sparer: 56,00 DKK pr m2

Vinyl

Alle informationer på denne side er kopieret materiale fra Gulvfakta som er et fagteknisk opslagsmateriale, Kilde: Gulvfakta

Vinyl er den dagligdags betegnelse for PVC, der er en forkortelse for PolyVinylChlorid. PVC er et kunststof med en række gode egenskaber, der bl.a. gør det velegnet til gulvbelægninger. For at opnå de ønskede egenskaber tilsættes der forskellige hjælpematerialer ved fabrikationen, fx stabilisatorer, blødgørere, farvestoffer og eventuelt fyldstoffer. Belægning af vinyl er ofte forsynet med en rengøringsvenlig og slidstærk overfladebeskyttelse i form af polyuretan eller tilsvarende. PVC gulv eller vinylgulv er har utrolig høj slidstyrke, hvorfor vinyl som belægning anvendes i mange danske hjem.

1.3.2.1 Introduktion

1.3.2.2 Egenskaber

1.3.2.3 Lægning og brug

1.3.2.4 Vådrum

1.3.2.5 Rengøring

1.3.2.6 Checkliste 3, 4, 5 og 6

Alle informationer på denne side er kopieret materiale fra Gulvfakta som er et fagteknisk opslagsmateriale, Kilde: Gulvfakta

1.3.2.1 Introduktion

Et vinylgulv anvendes i mange skoler, sygehuse, kontorer, butikker, boliger, etc. Da vinylgulve er nemme at renholde og kan udføres vandtætte, er de også anvendelige i baderum, rengøringsrum, storkøkkener, laboratorier og lignende. Vinylbelægninger fås i forskellige varianter, som hver især findes i mange farver og mønstre. Nogle af produkttyperne kan endvidere leveres med prægede overflader. Vinylbelægninger produceres som banevarer eller som fliseprodukter. Overfladen af vinyl er glat og nem at renholde. Vinyl har god modstandsevne mod vand og de fleste sure og alkaliske materialer. Vinyl fås også med en mere ru overflade til brug på steder, hvor der stilles krav om en forøget skridmodstandsevne.

Langvarig påvirkning af olie, asfalt, gummi mv. kan medføre, at farvestoffer kan vandre ind i vinylen og medføre misfarvning. Vinyl tåler ikke cigaretgløder og visse organiske opløsningsmidler. Vinyl, der anvendes som gulvbelægning, skal være CE mærket. CE mærkning af elastiske gulvbelægninger er omtalt i afsnittet om CE mærkninger af elastiske gulvbelægninger.

Vinyl der benyttes som gulvbelægning i flugtveje og andre områder med krav til brand og røgudvikling, skal have dokumentation for at opfylde den europæiske brandklasse Dfl-s1 i henhold til DS/EN 13501-1 (klasse G gulvbelægning). For alle typer af klassificerede vinyler ydes der 5 års slidgaranti i henhold til GSOs regler for materialegaranti, under forudsætning af, at leverandøren har godkendt anvendelsesområdet.

Hos gulvlageret fører vi et bredt sortiment af vinylgulve til enhver smag. Vi har både vinylgulv i ruller, vinylgulv med kliksystem, vinyl til vådrum, Vinyl Loose Lay og vinylgulve til limning. Tag et nærmere kig på Amaron vinyl sildebensparket Preston oak, BiClick vinyl klikgulv Monumental Oak eller Start klassisk bøgeparket vinylgulv.

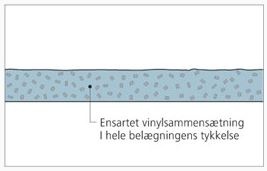

Homogene vinylbelægninger

Homogen vinyl består af en ensartet gennemfarvet masse. Eventuelt mønster går igennem hele belægningen. Homogen vinyl fås i tykkelser fra 1,5 mm til 4,0 mm. Det leveres i baner med bredder mellem 1,2 og 2 m og en del leveres desuden i form af fliser, som fås i formater mellem 250 x 250 mm og 610 x 610 mm.

Homogen vinyl kan leveres som elektrostatisk afledende gulvbelægning til anvendelse i rum med krav til personafladning. Leverandøren kan give detaljerede oplysninger om belægningernes elektriske modstandsevne.

Heterogen vinyl

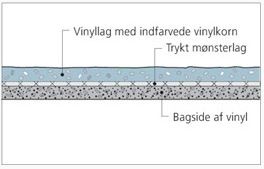

Heterogen vinyl består af et slidlag og andre kompakte lag, som kan variere i sammensætning og mønster. Belægningen kan indeholde en armering.

Heterogen vinyl kan leveres som elektrostatisk afledende gulvbelægning.

Vinyl med forøget skridmodstandsevne

Vinyl med forøget skridmodstandsevne indeholder kvartskorn, aluminiumskorn eller lignende, som kan være i overfladen eller i hele belægningstykkelsen. Klassifikationen til forskellige brugsområder sker på grundlag af en slidtest udført i henhold til DS/EN 13845. Afhængigt af partikeltabet, som højst må udgøre 10% efter henholdsvis 20.-, 30.-, 40.- eller 50.000 rotationer, kan belægningerne klassificeres til brug i bolig, erhverv eller industri. Skridmodstandsevnen prøves på en våd testrampe i henhold til DS/EN 13845, hvor en forsøgsperson bevæger sig frem og tilbage, mens rampens hældning gradvis øges til den opnår en vinkel på 45°. Skridmodstandsevnen bestemmes dels med fodtøj (ESf), hvor rampens hældning skal være større end 20° før forsøgspersonen skrider og dels som en barfodstest (ESb), hvor den opnåede hældning skal være større end 15°.

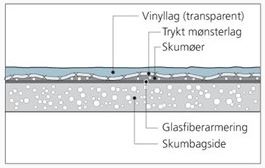

Mangelfuld eller forkert rengøring og pleje - herunder brug af uegnede rengørings- og plejemidler - vil forringe gulvets skridmodstandsevne. Du kan finde flere informationer om testmetoder m.v. i afsnittet omkring skridsikkerhed. Cushion-vinyl er flerlagsbelægninger, som øverst har et slidlag af klar pvc og i midten et lag opskummet pvcmateriale med trykt mønster. Nederst et stabiliseringslag, som yderligere kan være forsynet med en armering af glasfiber eller mineralfibre.

Cushion-vinyl leveres som banevare i bredder fra ca. 1,8 m til 4,0 m. Tykkelser op til 5 mm.

Cushion-vinyl anvendes primært i boligsektoren. I objektsektoren (erhvervssektoren) bør cushion-vinyl kun anvendes i samråd med leverandøren.

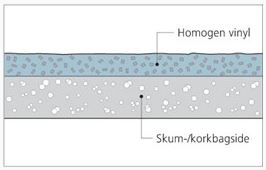

Vinyl med underlag af skum eller kork

Disse produkter består af et underlag af skum eller kork, hvorover der ligger et vinyl-slidlag. Vinyl med underlag af skum eller kork findes i mange forskellige kvaliteter. De leveres i tykkelser fra ca. 2,5 - 6,5 mm. og i bredder fra ca. 1,2 til 2,0 m. Vinyl med skum- eller korkunderlag anvendes i boligsektoren, skoler, sygehuse, kontorer, butikker, sportshaller etc.

Kvartsvinyl

• Kvartsvinyl fremstilles af PVC med et stort indhold af fyldstoffer især kvarts. Dette medfører, at belægningen bliver slidstærk overfor tung trafik og mere åben for vanddampdiffusion end andre typer af vinyl-belægninger. Kvartsvinyl leveres som fliser i formaterne 300 x 300 mm eller 600 x 600 mm og i tykkelserne 2,0 til 3,2 mm.

• Kvartsvinyl anvendes primært i objektsektoren, hvor der er krav om stor holdbarhed over for tung last, fx supermarkeder, varehuse, butikker, forsamlingslokaler etc. Limning af kvartsvinyl skal ske i overensstemmelse med limleverandørens anvisning.

• Kvartsvinyl kan ikke udføres vandtæt og kan derfor ikke benyttes i vådrum.

1.3.2.2 Egenskaber

Produkter, som opfylder den europæiske standard DS/EN 10581, skal overholde specifikke krav til:

• Længde, bredde, rethed og fladevægt

• Dimensionsstabilitet og formstabilitet efter varmeeksponering

• Tykkelse, fleksibilitet og modstandsevne mod indtrykningsmærker

• Farveægthed mod kunstigt lys.

Hvis der benyttes vinyl, som ikke er EN-klassificeret (cushionvinyl, vinyl med underlag af skum eller kork), må den projekterende selv påse, at belægningen har de egenskaber, som er relevante. EN-klassificerede vinylbelægninger har lidt forskellige afvigende specifikationer, afhængigt af typen. Dette fremgår af de respektive standarder: DS/EN 10595, semifleksible PVC-fliser og DS/EN 650, PVC-gulvbelægninger med bagside af filt mm.

Udover de egenskaber, der indgår i klassifikationen, vil der ofte være behov for at stille krav til andre egenskaber, afhængigt af den aktuelle anvendelse. Disse egenskaber indgår i Gulvbranchens supplerende egenskaber, som for vinyl omfatter:

Krav til udførelsesstedet

Der skal være afsat tid til, at vinylen kan akklimatiseres. Akklimatiseringen sker bedst ved at banerne efter opskæring udlægges løst over gulvet. Eventuelt kan de opskårne baner efter opskæringen stilles lodret i løst oprullet form. Fliser anbringes i uåbnet emballage i det rum, hvor de skal anvendes. Akklimatiseringen skal vare i mindst 24 timer. En emballeret rulle vil selv efter længere tids opbevaring i bygningen ikke kunne forventes at være i fugtmæssig ligevægt med omgivelserne.

Under og efter limning af vinyl skal temperaturen i luften og undergulvet være 17-25°C og luftfugtigheden mellem 35%-75% RF. Underlaget skal have samme planhed, som kræves af det færdige gulv, normalt ± 2 mm på et 2 m retholt. Planhed og gulve, herunder krav og målemetoder, er beskrevet i afsnittet planhed og gulve. Skal vinylen udlægges direkte på støbte dæk, må betonens porefugt (restbyggefugt) højst være 85% RF (for kvartsvinylfliser dog højst 90% RF). Fugt og gulve, herunder krav og målemetoder, er ligeledes beskrevet i afsnittet om byggefugt

Der må ikke være kraftig træk eller kraftigt solindfald under lægningen af gulvet.

1.3.2.3 Lægning og brug

Forhold i forbindelse med lægning og brug

Korrekt friskæring i banesamlinger er vigtig, da limfugen i første del af limens hærdefase ikke vil kunne fastholde belægningen til underlaget, hvis der sker sammenpresning i samlingen. Leverandørens anvisninger om udførelse af til- og sammenskæringer skal følges.

Vinyl kan enten lægges med stødte samlinger, hvilket fx ofte anvendes ved mønsterlægning, eller ved at fugerne svejses. Tæt tilskæring til lodrette flader er ikke mulig. Derfor vil det være nødvendigt at montere lister, hvis der ikke ønskes en synlig fuge langs gulvet. Lægning af vinylen skal ske inden for en vis tid efter at limen er påført (monteringstiden), for at sikre god klæbning og dermed den bedste vedhæftning. Monteringstiden afhænger af de materialer, der skal klæbes sammen, og af fugt- og temperaturforholdene i rummet.

Svejsning

Vinylgulve, som udsættes for vandpåvirkning, fx i baderum, skal svejses i banesamlingerne. Til svejsning af banesamlinger anvendes svejsetråd, der er anvist af leverandøren. Svejsning må ikke foretages før limen er tilstrækkeligt hærdet. Efter svejsningen skal tråden afskæres i niveau med overfladen af banerne, så rengøringsvand og snavs ikke samler sig i og omkring svejsefugen. Svejsefuger skal fremstå glatte og ensartede.

Elektrostatisk afledende gulve

Homogene og heterogene vinylbelægninger er egnede som ledende gulvbelægning og kan anvendes i lokaler, hvor der er behov for en bortledning af elektriske opladninger. Elektrostatisk afledende vinylgulve udføres ved hjælp af afledende vinylbelægning. Gulvet skal desuden være forbundet til jord gennem kobberbånd. Det skal aftales, hvor gulventreprenøren skal føre kobberbåndet op ad væggen.

Udførelse af elektrostatisk afledende vinylgulve skal foretages i samråd med belægningsleverandøren. Jording skal foretages af en autoriseret el-installatør. Statisk afledende og statisk ledende elastiske gulvbelægninger - begreber, krav m.m.

1.3.2.4 Vådrum

Homogene og heterogene vinylbelægninger med dokumentation for at opfylde særlige kvalitetskrav kan anvendes som vandtæt belægning af gulve og vægge i vådrum. Beklædning med pvc i vådrum er beskrevet i Vådrumsfakta, som udgives af Gulvbranchens Vådrumskontrol og Byg og Byg Anvisning 200, som er udgivet af Statens Byggeforsknings Institut.

1.3.2.5 Rengøring

De fremtidige brugere skal oplyses om korrekt rengøring, da forkert rengøring kan medføre skader på overfladen. Leverandørens anvisning om rengøring og vedligeholdelse af vinylgulve skal udleveres til brugeren. Til daglig rengøring anvendes fortrinsvis tørre metoder dvs. tør eller fugtmopning eller støvsugning og vask efter behov. Til kraftigere, lejlighedsvis rengøring anvendes et universalrengøringsmiddel eller vaske-/plejemiddel. I områder, hvor det er nødvendigt med vådrengøring i større omfang, skal banesamlinger svejses. Rengøring af vinylgulve er omtalt i sektionen om rengøring.

1.3.2.6 Checkliste 3, 4, 5 og 6

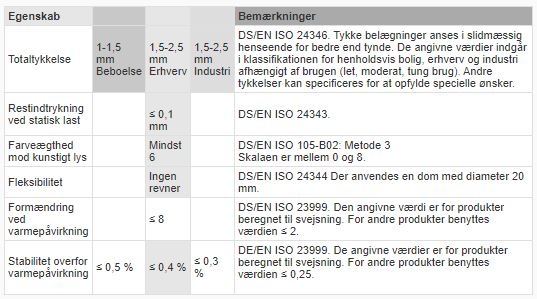

Checkliste 3. Egenskaber, som indgår i EN-klassifikationen for homogene og heterogene vinylgulvbelægninger. Klassifikationen sker på grundlag af totaltykkelsen og tykkelsen af slidlaget. For klasserne Erhverv og Industri har svejsesømme i belægningen en styrke over 240 N/50 mm, og for Erhverv Moderat og højere er belægningerne egnet til brug med kontorstolshjul. Øvrige egenskaber overholder for EN-klassificerede produkter de markerede værdier.

Checkliste 4. Supplerende egenskaber for homogene og heterogene vinylbelægninger, som der kan være behov for at stille krav til, fx på grund af særlige påvirkninger af gulvet ved den aktuelle brug.

(*) I flugtveje skal vægbeklædning være klasse K1 10B-s1,d0 iht DS/EN 13501-1. Der henvises til leverandørerne og DBi for yderligere information.

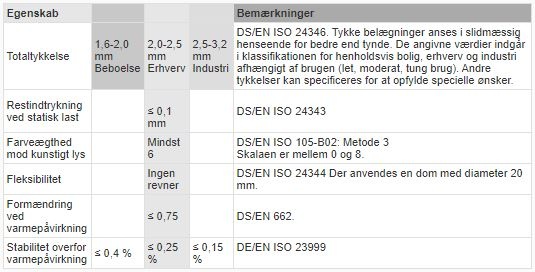

Checkliste 5. Egenskaber, som indgår i EN-klassifikationen for semi-fleksible vinyl-fliser. Klassifikationen sker på grundlag af totaltykkelsen og tykkelsen af slidlaget. Øvrige egenskaber overholder for EN-klassificerede produkter de markerede værdier.

Checkliste 6. Supplerende egenskaber for semi-fleksible vinylfliser, som der kan være behov for at stille krav til, fx på grund af særlige påvirkninger af gulvet ved den aktuelle brug.