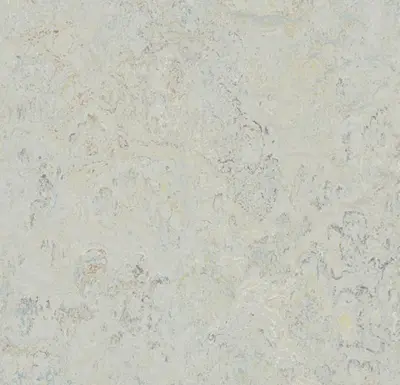

Marmoleum Splash - Seashell

Fremstillet af naturen, fornybare råvarer, Marmoleum linoleumsgulve er det mest bæredygtige elastiske gulv på markedet. Lave emissionsniveauer og uden syntetiske tilsætningsstoffer. Marmoleum gulve har modtaget mange kvalitetsmærker og certificeringer i verden for at være miljøvenlig.

Tykkelse: 2,5 mm

Rullebredde: 200 cm

Rullelængde: Op til 32 meter.

NCS: S 3005-G80Y

LRV: 45%

Download:

Rengøringsvejledning

Monteringsvejledning

Storslået fra naturens side

97 % naturlige råvarer

72 % hurtigt fornyede materialer

43 % genbrugsmaterialer

Højeste ydeevne skabt af naturen

De naturlige og vedvarende råstoffer gør Marmoleum til det mest holdbare elastiske gulv på markedet. Det er PVC-fri og indeholder ingen blødgørere eller mineralolier.

De vigtigste ingredienser i Marmoleum er:

Linolie, som kommer fra hørplantens frø

Træmel fra kontrollerede skove

Jute, det naturlige bærervæv, som udgør bagsiden af linoleum

Marmoleum har de vigtige globale miljømæssige certifikater såsom Svanen og Blue Angel.

Topshield er Forbos højtydende UV finish, som udgør overfladen på alle Marmoleum banevarer og fliser. Topshield som gør belægningen modstandsdygtig over for pletter, ridser og snavs og skaber et langtidsholdbart smukt gulv. Det gør også gulvet lettere at rengøre og vedligeholde år efter år.

Rengøring af Marmoleum gulve

Forbos gulvbelægninger imødekommer de store krav, der stilles til gulve i både private hjem og offentlige miljøer. Gulvene skal kunne fungere i mange år under kraftige påvirkninger og samtidig bevare det flotte udseende og høje ydeevne.

Der er en klar sammenhæng mellem, hvordan gulve ser ud, og den måde man rengør og vedligeholder dem. Fremgangsmåden, hyppigheden af rengøringen og midlerne afhænger af de påvirkninger gulvet udsættes for.

Nemt at montere

For at opnå et perfekt resultat er det vigtigt, at gulvbelægningen monteres korrekt. Se vores monteringsvejledninger.

Nøglefaktorerne for en vellykket montering af et slidstærkt gulv er følgende:

Klargøring af undergulvet

Montering af et slidstærkt Forbo-gulv begynder med undergulvet, som skal være tørt, stabilt og plant. Forbo QuickFit er et træfiberbaseret, hurtigt monteret, alternativ til det traditionelle undergulvssystem. Forbo QuickFit er især velegnet i mindre områder, hvor der skal monteres uden brug af søm, og lim og på steder hvor der evt. er brug for ekstra trinlyddæmpning.

Monteringsplan

Det er vigtigt at udarbejde en god plan, før monteringen påbegyndes. Rum, materialer og undergulve skal have en temperatur på minimum 17 grader. Materialerne skal have tid til at akklimatisere minimum natten over før montering.

Ridsning og skæring

En god start er afgørende: Vær særligt opmærksom på den første bane! Et perfekt resultat opnås ved hjælp af professionelt monteringsværktøj.

Klæbning

Et perfekt monteret gulv kræver perfekt klæbning. Husk at tromle gulvet efter montering for at opnå en korrekt limfuge. Følg iøvrigt altid limproducentens anvisninger.

Efter montering er det vigtigt, at rummet ventileres, så limen kan tørre. Et nymonteret gulv må ikke anvendes eller påføres vægt, før limen er tørret helt, hvilket kan tage op til 2 dage.

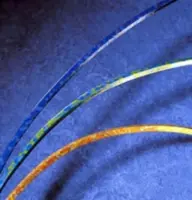

Svejsning

Svejsning foretages som dekoration og/eller af rengøringsmæssige årsager. Når limen er tilstrækkelig hærdet, hvilket normalt varer en dags tid, kan smeltetråden monteres. Følg anvisningerne i vores monteringsvejledning og på siden af svejsetrådsrullen grundigt.

Finish

For at opnå et professionelt færdigt resultat skal gulvet have en finish, og der findes naturligvis mange kvalitetsprodukter til dette formål. Fodpaneler, trappekanter og overgangsprofiler i forskellige materialer kan bruges til at skabe et perfekt resultat.